EMP is a global, full-service manufacturer of precision aluminum die casting products. With more than 30 years' experience in research & development, manufacturing, and precision machining for the aluminum die casting industry, we are proud to work with some of the world's top automotive, engineering, electronics, and industrial companies.

1. One-stop service on your projects, such as tool design and manufacture, Die Casting, CNC Machining, Prototypes, and extensive product testing.

2. Prompt Molding and Sampling time less than 50 days, to catch up with your product development and make your clients happy.

3. Reliable product quality, more than 60 sets of advanced automatic production facilities invested, providing customers products with high quality and competitive price.

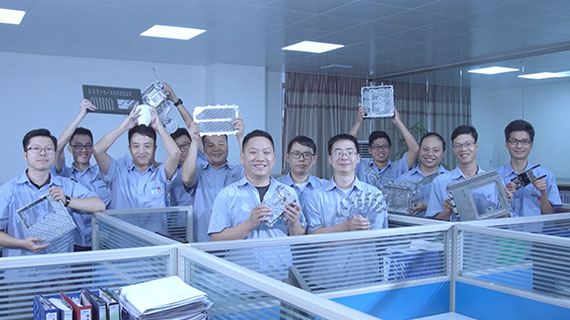

Full-experienced R&D Team. 2 days accurate assessment is available with a group of professional engineers who owned over 8 years' experience in die casting projects.

Fast response and offer. Providing you the best offer for your custom projects, utilizing the most advanced equipment and techniques available today.

Equipped with 12 sets of large die casting machines from 350T-3050T to meet customer’s project needs, deliver an output of 70,000 tons of aluminum alloy parts each year.

We have dedicated over 30% of our staff to our quality control efforts and implement quality control in all phases of production.

We mainly manufacture aluminum die casting products in the automotive, electric vehicle, and machinery industries which supplied 60+ countries around the world.

We're here to turn your ideas into reality quickly, accurately and at a competitive price:

Full-experienced R&D Team. Quick feedback and accurate assessment is available with a group of professional engineers who owned over 8 years' experience within EV products.

One-stop service on your projects, such as tool design and manufacture, Die Casting, CNC Machining, Leakage test.

Prompt Molding and Sampling time less than 50 days, to catch up with your product development and make your clients happy.

Reliable product quality, more than 60 sets of advanced automatic production facilities invested, providing customers products with high quality and competitive price.

IATF 16949(VDA6.3) certified factory, 30% of total staff are QC members who monitor the entire manufacturing process.

12 sets, 350T-3050T, 150+ sets CNC machines

With great communication skills and experience, we are willing to work through problems, and proactive in offering advices.

We've been serving the top brands like Daimler, Continental, Scania from the begining of our foundation.

We help to solve your problems, from design to reality.

We are here whenever you need, any of your inquires or questions will be handled within 12 hours.