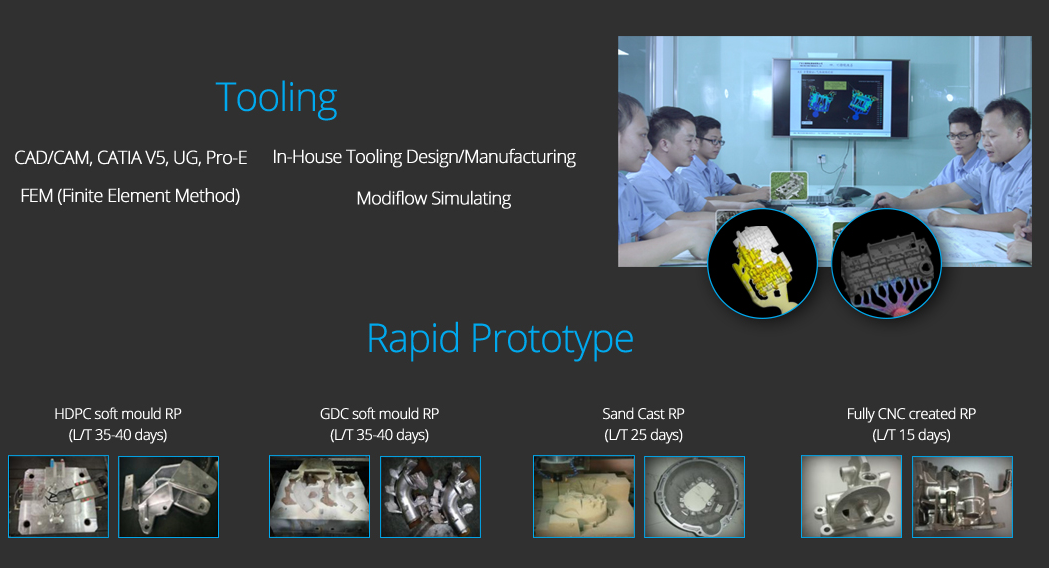

New technology is breaking through constantly, driven by innovative thinking. The die casting tool design team carries out new product development through professional 3D model design as well as mold flow analysis and validation to assure customers with satisfactory products.

Mold workshop is equipped with a group of professional mold design&manufacturing engineers who are proficient at computer software such as 2D/3D to assist mold design, manufacturing machines which includes CNC machining centers, EDM, WEDM, universal milling machines, friction welding equipment, etc.

Optimizing die casting process is an important step to improve efficiency and optimize die casting design. All types of die casting are used for production, so it is very important to consider the production process in the design process. Pursue the efficiency of manufacturing and reduce secondary operations, which is called "Design for manufacturing" to minimize costs before the project is put into operation, in order to prevent the reduction of efficiency.

EMP has advanced engineering and works cooperatively with customers with well-designs for cost-effective fabrication.

At the beginning, to meet customer’s requirements, we will communicate with the customers to discuss more details per drawings and gather their needs. Then we use tools such as FEA, mold flow simulation to clarify and identify critical open issues that could be resolved to make sure producing the part successfully.

In addition, some prototyping options also support our product development and casting part design process. As one of the top 10 aluminium die casting manufacturers in China, EMP, with die casting mold and tools factory, can provide rapid prototypes within 20 to 35days and HPDC components – all with engineering support to see results and recommend if necessary changes.