Looking for a high-quality Electric Vehicle Motor Controller Housing?

Look no further than our top-of-the-line products! EMP EV control housing is designed with the latest technology and materials, ensuring a durable and reliable solution for your EV motor controller. Trust us to provide you with a high-quality Electric Vehicle Motor Controller Housing that is both affordable and efficient. Contact us today to inquiry now!

Material | Aluminum Alloy ENAC 43400 / EN AC 46400 / AlSi10MgFe / ADC12 |

Processing/Services | Design and Tooling - Aluminum Die Casting - Deburring - Friction Stir Welding - CNC Machining -Full Inspection - Cleaning - Leakage Test - Final Inspection - Packing - Delivery |

Certification | IATF16949, ISO9001, ISO14001, ROHS certification of all aluminum die casting parts |

Die Casting Machine | 1250T-3050T |

Inspection Equipment | Friction Stir Welding, Leakage Test, X-ray, CMM, Ultrasonic cleaning, Mechanical Properties, Full Dimension Inspection so on. |

Annual Capacity | 60,000 - 80,000 pcs |

Application | Electric vehicle motor controller unit , OBC unit, and all-in-one combo unit for electric vehicle |

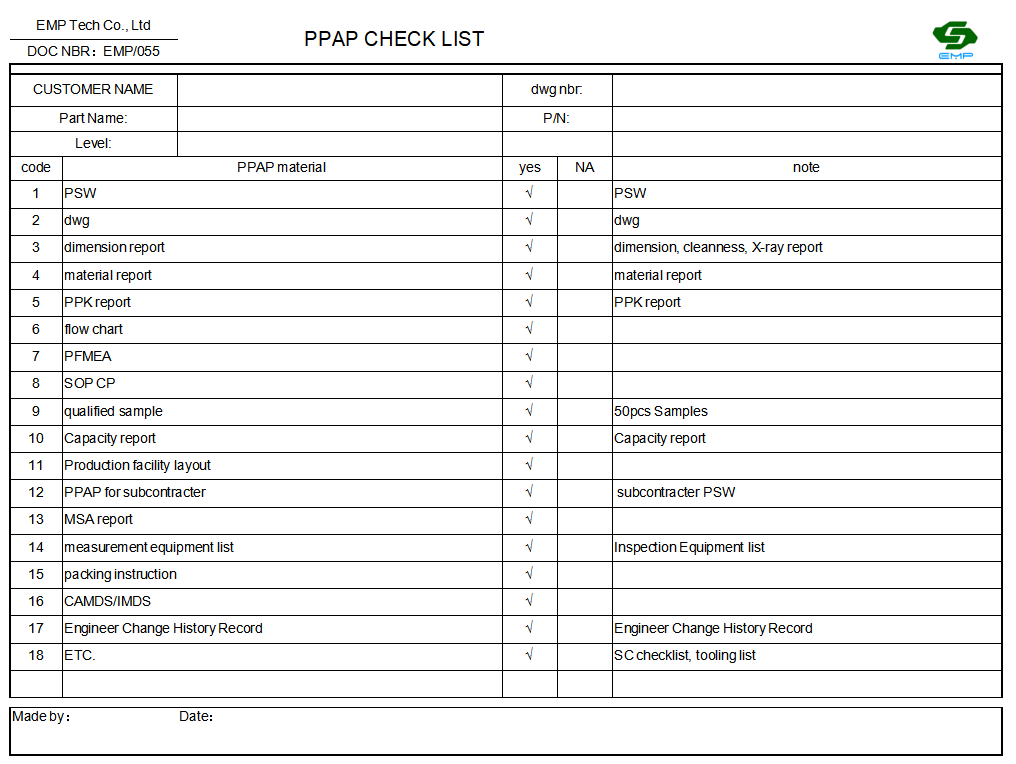

PPAP Standard | PPAP Level 3 |

Raw material - Die casting - Deburring - Shot Blasting - Friction Stir Welding - CNC Machining -Leakage Test - Cleaning - Full inspection - Packing - Delivery

1. Friction Stir Welding

Friction welding process for our electric vehicle motor housing for reference only.

2. Leakage Test Video

3. Cleanliness Process Video

Cleaning standard per VDA 19.1

EMP complies with PPAP level 3 of the parts to ensure quality and production.

Full-experienced R&D Team. Quick feedback and accurate assessment is available with a group of professional engineers who owned over 8 years' experience within EV products.

Prompt Molding and Sampling time less than 50 days, to catch up with your product development and make your clients happy.

Reliable product quality, more than 60 sets of advanced automatic production facilities invested, providing customers products with high quality and competitive price.

One-stop service on your projects, such as tool design and manufacture, Die Casting, CNC Machining, Leakage test.

Working with EU&US automotive projects for years, such as Daimler, VW, Ford, BYD, Man, etc.