Friction welding is a pressure welding method that uses the heat generated by the relative frictional movement of the weldment to achieve reliable connection of materials.

The welding process is under the effect of pressure, the friction between the materials to be welded increases the temperature of the interface and its vicinity and reaches in the thermoplastic state, with the action of upsetting force, the interface oxide film is broken, the material undergoes plastic deformation and flow, and the joint is formed by the interface element diffusion and recrystallization metallurgical reaction.

EMP Tech Co., Ltd, offering professional friction welding services, can finish many kinds of friction welding, including the continuous drive friction welding, rotational friction welding and orbital friction welding, etc..

The surface temperature of friction welding is the temperature of the heat source of friction welding, which will directly affect the heating temperature and temperature distribution of the joint and the deformation and diffusion of the joint metal. In the process of friction heating, the friction surface can also adjust the friction heating power through the influence of the friction coefficient, so that the heating power and the temperature of the heat source are in balance. Welding test and production practice show that when the diameter of the workpiece increases, the rotation number increases and the friction pressure increases, the temperature of the friction welding surface increases. Otherwise, the surface temperature of friction welding will be reduced.

Heating deforms the material, and the rotating tool stirs the material at the weld. In this way, friction welding technology creates a uniform structure with excellent performance. The whole process is emission-free. When welding must be very tight, friction welding is the preferred method. It can connect the workpiece with repeatable pressure and medium seal. Friction welding can be optimized and integrated into industrial batch production. The result is top quality that is easy to copy.

As a machinery parts manufacturer, we provide various products and services in this area, and actually friction welding services and production, continuous drive friction welding, phase-controlled friction welding, inertial friction welding and friction stir welding are more common used.

Durable, medium-sealed and pressure-sealed welds.

Height, repeatable seam quality.

Low warping joint.

No pores or hot cracks.

No exhaust emissions, no shielding gas, powder, welding wire and other auxiliary materials.

In actual friction welding services and production, continuous drive friction welding, phase-controlled friction welding, inertial friction welding and friction stir welding are more common.

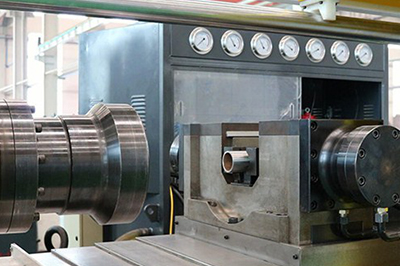

Friction welding machine is mainly used for welding of medium-sized shaft parts. It can weld a wide range of metals, and has the characteristics of stable performance, high production efficiency and low energy consumption, which is important for friction welding companies.

Rail friction welding is similar to rotary friction welding, but the two welding parts of rail friction welding rotate in the same direction and at the same speed,with axes offset up to 3 mm. At the end of the welding, the two parts return to the common shaft, the relative motion ends, and the welding relay remains intact or increases. Rail friction welding has the advantage of uniform surface velocity in the whole contact zone. You can connect non-circular components and multiple individual parts in a friction welding sequence. Although rail friction welding has been demonstrated in many materials and joint configurations, it is rarely used in industry.