Reasons:

① It is caused by the side and corner of the mold, equipment, or worktable when opening the mold.

② The castings of each operation process are stacked.

③ Improper behaviour of each process, such as throwing.

④ During operation and transfer between processes, the castings were not separated and protected, or the castings collapsed.

⑤ During each operation procedure, such as die-casting pick hooks, picking pliers, files and punches in the cleaning process.

5 ways of avoiding “scratches”:

① When the casting is demoulded, be careful not to bump.

② Obey the operating instructions, the castings are not allowed to be stacked and must be neatly placed in the workstation equipment one by one.

③ Not allowed throwing the castings during production, and must be handled carefully.

④ Placed the castings must be protected separately, and the transfer must be slow to prevent them from collapsing or falling.

⑤ Using the tools correctly. It is not allowed to hook or pinch the casting body when removing them from the moulds.

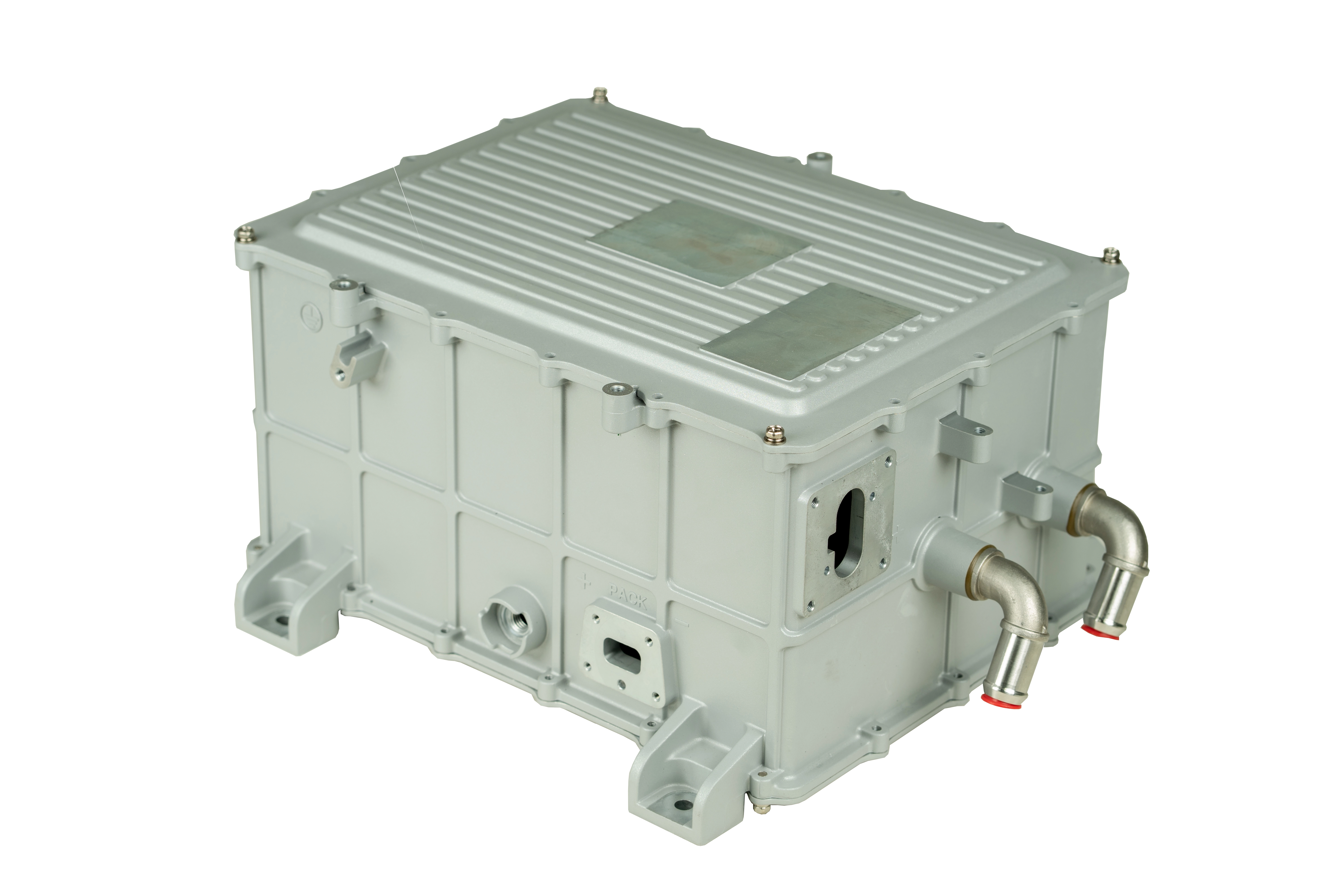

EMP treats every customer's project with a careful, scientific, and rigorous attitude, and we never allow the slightest flaw in the die-casting parts.