1、system integration as a definitive trend, is the choice of technological development and cost pressure

Electric drive system integration is a definite future trend, while integrated products also increase the barriers to entry in the industry, the technical level, the advantages of a more integrated product include:

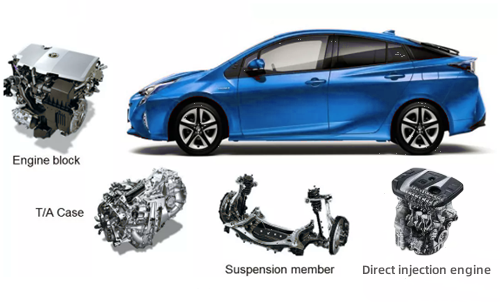

(1) The ability to integrate components such as housings and shafts reduces the number of parts used and the weight of components, resulting in cost savings.

(2) The integration of drive motor, drive motor controller and transmission can reduce the length of the three-phase wire connected to the controller and motor, which improves efficiency and saves wiring harness cost, and the performance of electromagnetic compatibility can be improved in the enclosed housing space; the common circuit board design of PDU, OBC and DC/DC converter can also reduce cost and product volume.

(3) The integrated products can be supplied by one company, and the design can be optimized at the initial stage to achieve the best cost of the system, saving cost and space, and making the assembly of the whole vehicle faster and quicker.

2、the size of the three-in-one products will maintain a period of time, all-in-one products gradually replaced

With the further integration of electric drive products, in addition to motors, motor controllers, gearboxes, high-voltage split boxes, DC/DC, chargers OBC and other components may also be integrated into the formation of a more fully functional all-in-one powertrain system. However, there will be a certain process from split parts to 3-in-1 becoming mainstream, and then from 3-in-1 to N-in-1 products. The main lies in:

(1) more components, integration difficulties, which in turn brings greater quality risks, and higher requirements for the ability of suppliers.

(2) N-in-one products are also more core, if the host plant itself is not able to integrate or master the integration capability is more worried about being constrained by the supplier.

(3) Charging and distribution and power system functions are relatively separate, and the cost reduction brought by integration is relatively less obvious.