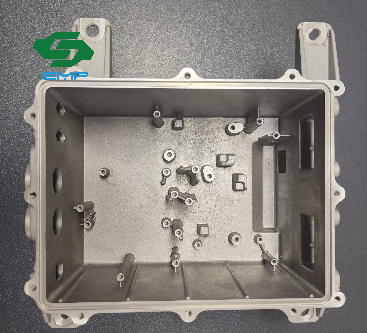

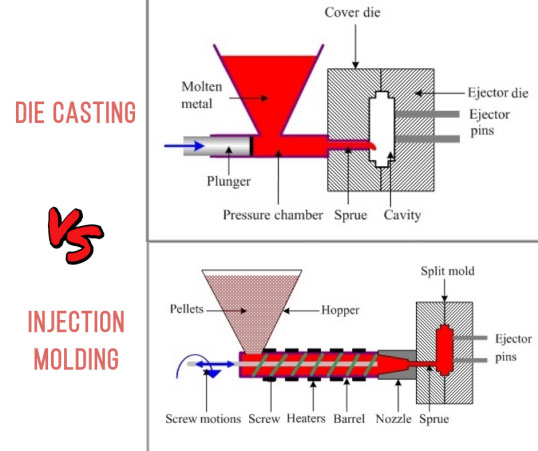

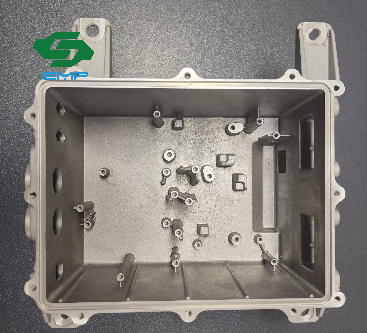

Aluminum die-cast housings are essential in industries like electric vehicles (EVs), automotive, and electronics, providing lightweight, durable, and precise components such as motor enclosures and battery cases. High-pressure die casting enables complex geometries but introduces machining challenges. Addressing these issues with advanced processes ensures reliable, high-quality housings for demanding applications.

Common Machining Challenges

Porosity and Voids: Gas entrapment or shrinkage during casting creates internal voids, reducing structural strength and compromising seals, especially critical for EV battery housings requiring airtight performance.

Surface Imperfections: Cold shuts, flash, or rough surfaces often occur, affecting both aesthetics and functionality. These defects can impair precision components like motor controller housings.

Dimensional Inaccuracies: Complex EV parts require tight tolerances. Mold wear or inconsistent cooling can cause deviations, leading to assembly mismatches.

Tool Wear: Aluminum’s abrasiveness accelerates wear on CNC tools, increasing costs and impacting surface quality during high-volume production.

Process Solutions

Effective manufacturing techniques mitigate these challenges to produce high-quality aluminum die-cast housings:

Mold Design Optimization: Using CAD/CAM and mold flow analysis, manufacturers can refine gating and venting systems to minimize porosity. This promotes uniform metal flow, reducing voids in critical components like EV battery cases.

Controlled High-Pressure Casting: Automated systems ensure consistent pressure and cooling rates, reducing cold shuts and achieving dimensional accuracy within ±0.01 mm for intricate parts.

Precision CNC Machining: Post-casting CNC processes eliminate flash and deliver smooth finishes. Specialized tool coatings, such as carbide or diamond-like carbon, extend tool life by up to 30%, enhancing efficiency and surface quality.

Comprehensive Quality Testing: Non-destructive methods like X-ray inspections and coordinate measuring machines (CMM) detect internal defects and verify tolerances, ensuring components meet industry standards.

Conclusion

Producing reliable aluminum die-cast housings requires overcoming porosity, surface defects, dimensional inaccuracies, and tool wear. By leveraging optimized mold design, controlled casting, precision machining, and rigorous testing, manufacturers can deliver components that meet the stringent demands of EVs and other industries. These solutions drive quality and performance in modern manufacturing.