In today's fast-paced society, where automobiles play an essential role in our daily lives, longevity and durability are crucial factors for automotive manufacturers. ADC12, a widely used aluminum alloy, offers exceptional properties that contribute to enhancing the longevity of vehicles. This blog explores the various ADC12 properties and how they positively impact the automotive industry.

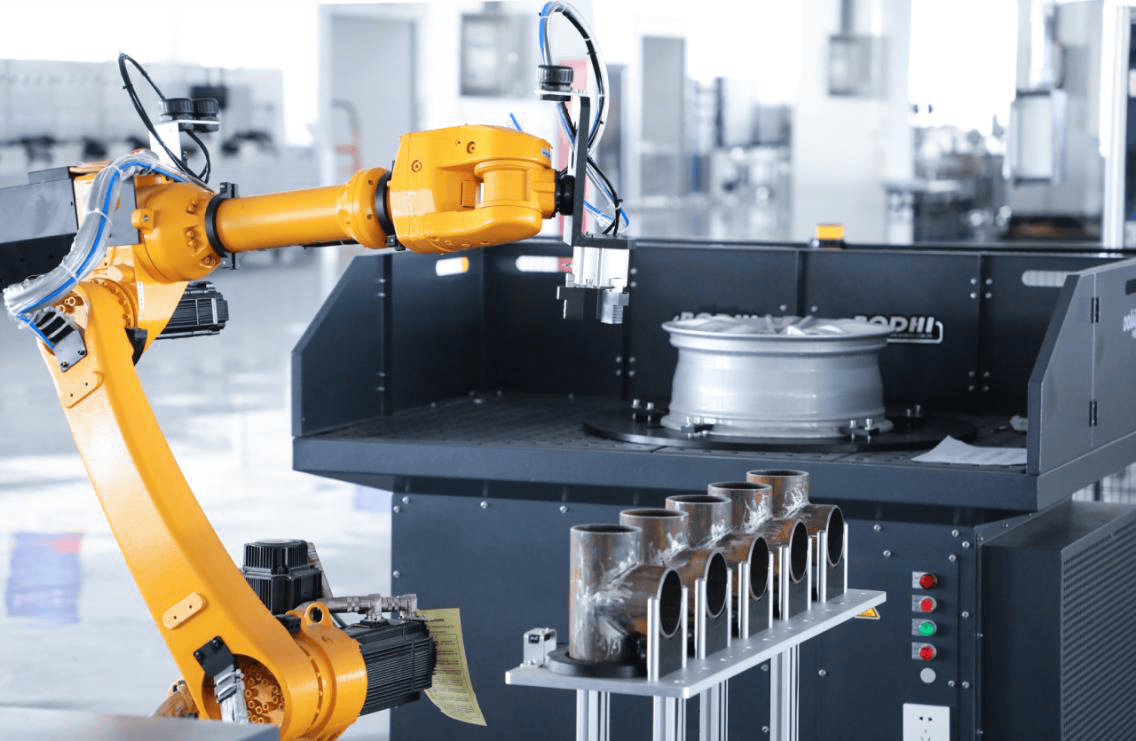

ADC12 is a high-quality and lightweight aluminum alloy widely utilized in the automotive industry. Combining aluminum, copper, and magnesium, ADC12 exhibits remarkable properties that make it an ideal material for manufacturing parts and components used in automobiles. Some of the key properties of ADC12 include high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity.

One of the significant advantages of using ADC12 in automotive manufacturing is its lightweight nature. With a density nearly one-third that of steel, ADC12 helps automakers significantly reduce the overall weight of the vehicle. This reduction in weight translates into improved fuel efficiency, reducing carbon emissions and enhancing the vehicle's environmental performance. Furthermore, lighter vehicles also experience reduced wear and tear, thereby enhancing their longevity.

ADC12 alloy is highly resistant to corrosion, making it an ideal choice for automotive applications. Due to prolonged exposure to various weather conditions, automobiles are susceptible to rust and corrosion. By utilizing ADC12 properties, manufacturers can enhance the longevity of vehicles by minimizing the effects of corrosion. This, in turn, reduces maintenance costs and extends the lifespan of the automobile.

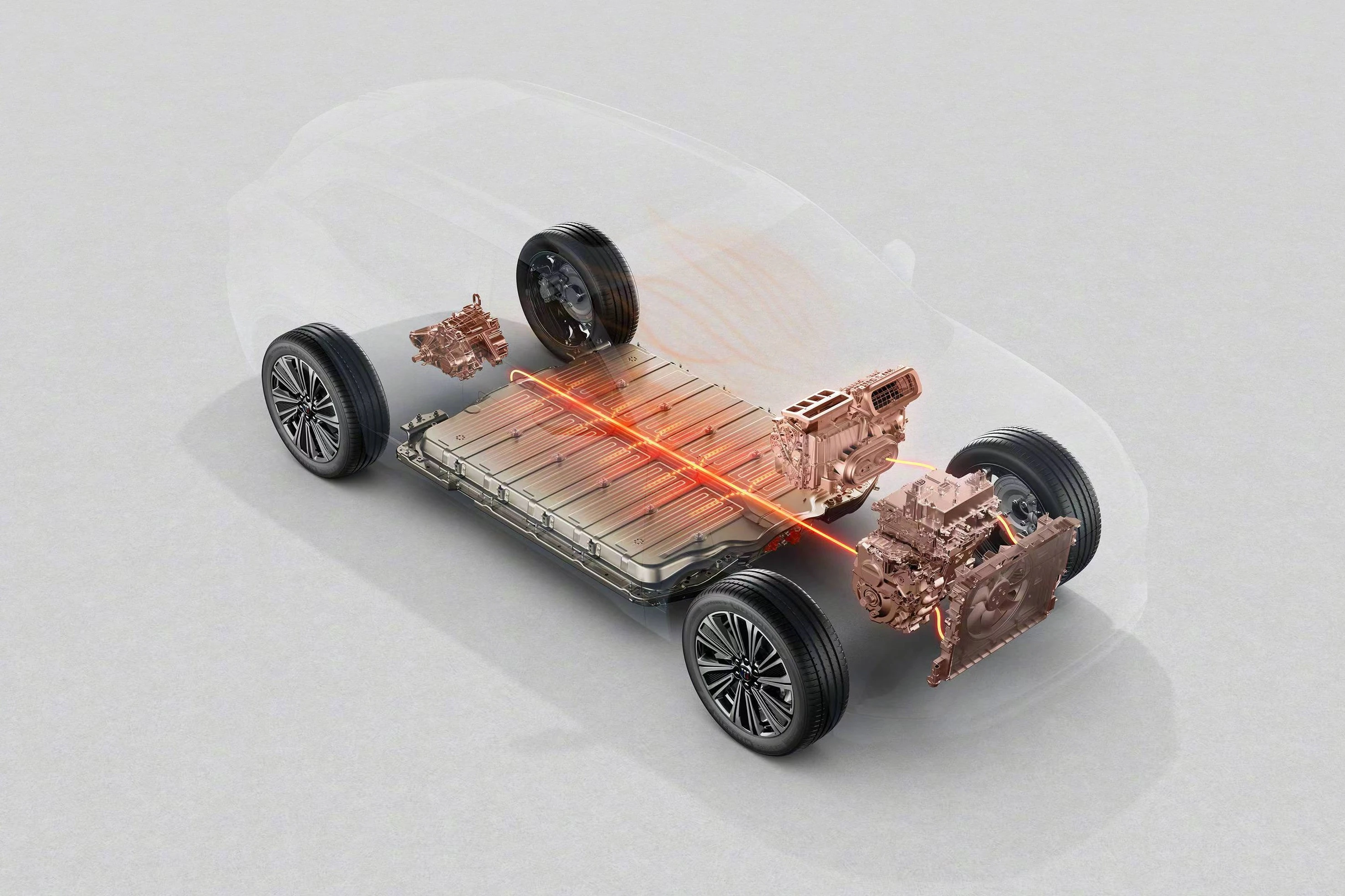

Thermal management is vital for the efficient functioning of automotive components. The excellent thermal conductivity property of ADC12 plays a crucial role in dissipating heat generated by the engine, brakes, and other critical components. Efficient heat dissipation prevents overheating and ensures the longevity and optimal performance of various automotive systems. By using ADC12, manufacturers can minimize the risk of component failures due to heat-related issues.

ADC12 properties have revolutionized the automotive industry, offering numerous benefits that contribute to the longevity and durability of vehicles. The lightweight advantage of ADC12 ensures enhanced fuel efficiency and decreased wear and tear, leading to a prolonged lifespan. Its exceptional corrosion resistance property further reduces maintenance costs and prevents the detrimental effects of rust. Lastly, superior thermal conductivity aids in efficient heat dissipation, ensuring the optimal performance and longevity of critical automotive components. With such outstanding properties, it's no wonder ADC12 continues to be a preferred choice for automakers worldwide, paving the way for longer-lasting, eco-friendly vehicles.