Features

Small heat-affected zone

Due to the millisecond pulse discharge time, the precise energy control (welding spot 1.6-2.0mm) does not affect the area outside the welding area. Therefore, the effect of cold welding is complete, and the base material will not be thermally deformed.

Thin welding thickness

Since the Controllable melting depth is within 0.1-0.8mm, it is possible to weld aluminum alloy thin plates below 0.2mm.

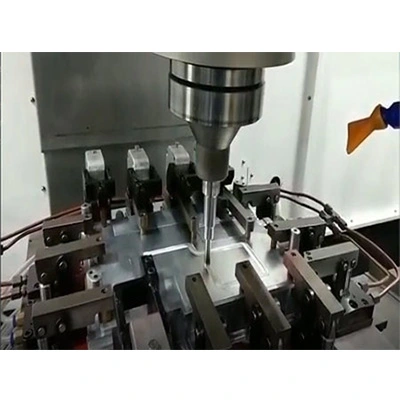

Highly integrated

Using metallurgical bonding (base metal and welding material are fuses), the bonding strength after welding is high, and it can adapt to various processing forms without falling off.

High repair welding efficiency

Use an automatic wire feeding torch. (The diameter of the welding wire is 0.8-1.2mm, and the diameter of the welding spot is 1.6-2.0mm.) Therefore, the formation time of instant heating solder joints is short.

Scope of application

Aluminum alloy pressure vessels, such as aluminum alloy condensers, radiators, evaporators, etc. Spores produce after argon welding or brazing.

Defects such as pores, shrinkage holes, and trachoma in aluminum alloy low-pressure castings or die castings. For instance: motorcycle aluminum alloy pistons, wheels, cylinder heads, straws, shells, and other accessories. There are also aluminum alloy casings for electrical appliances and communication equipment.

Repair mold wear, such as the texture of aluminum alloy shoe molds. Repair of logo wears, etc.

Repair defects of various aluminum alloy materials.