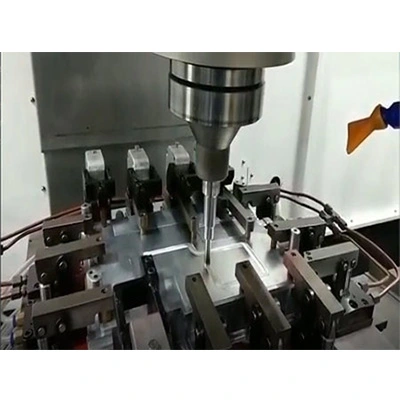

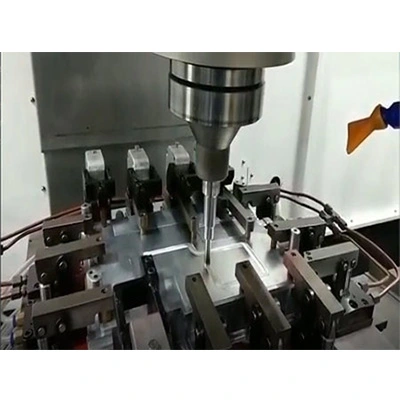

To meet the technical requirements for manufacturing aluminum die casting parts used in new energy vehicle and 5G industry, our factory has equipped itself with a new machine in 2020 ---the large-scale friction welding equipment .

This equipment can help with manufacturing various products like electric vehicle products, battery housing, motor housing and controller housing , telecommunication filter and heat sink parts.

If any of your project involves above parts, EMP team is happy to help.