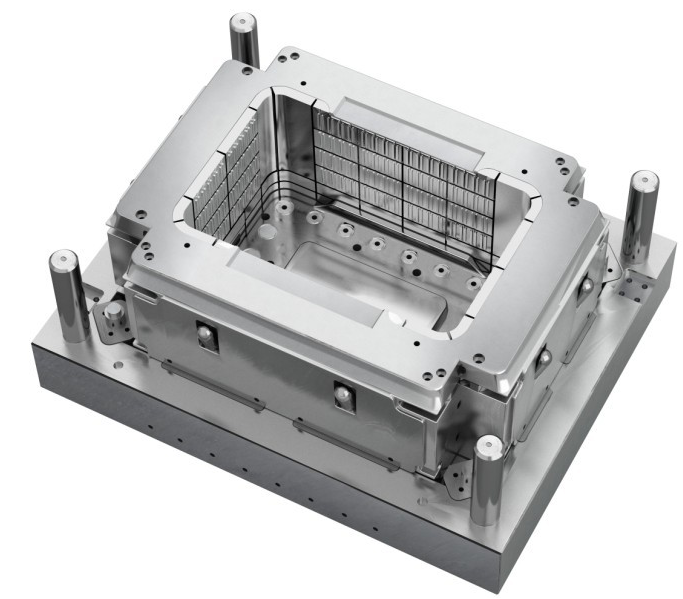

1. Mold design

Try to avoid sharp corners in the mold design, and the positions of holes and slots should be arranged reasonably.

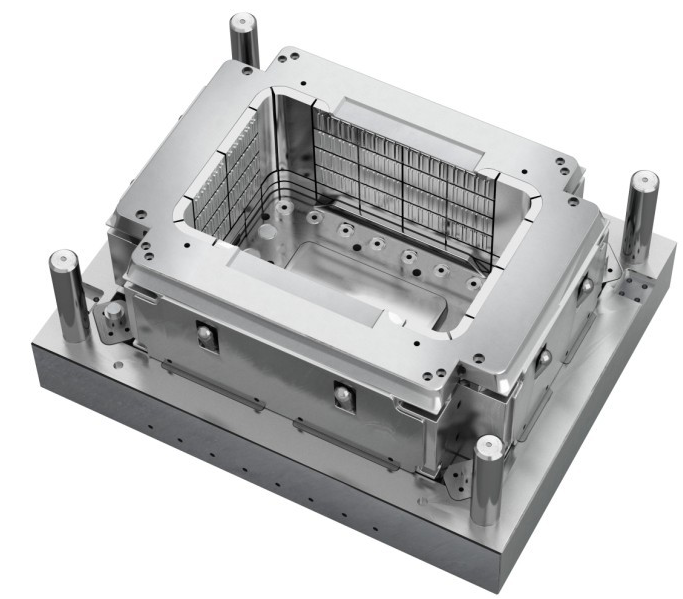

2. Selection of die steel

The selection of die steel must complete the use of heat treatment to eliminate carbide segregation, refine carbide, and uniform structure.

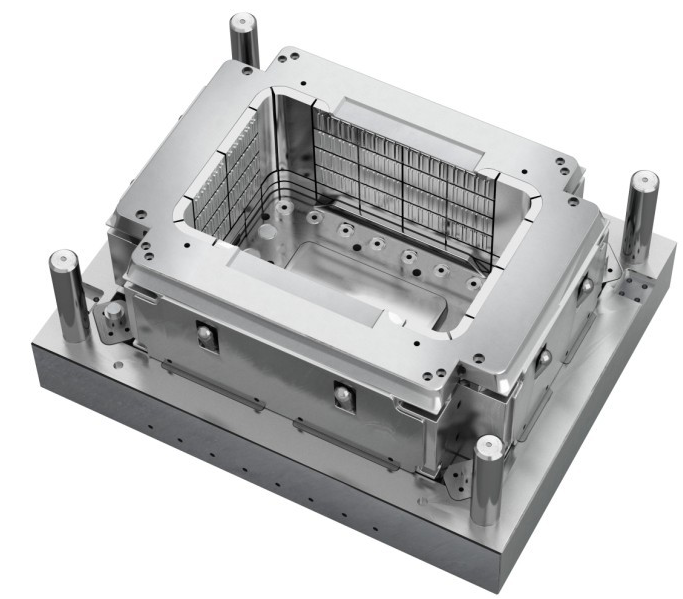

3. Cooling and lubrication

The cooling and lubrication of the mold are to reduce the thermal load of the mold and avoid the mold temperature from being too high. It is usually forced to cool the mold during the intermittent operation, which will cause the mold's periodic heating and chilling action to cause thermal fatigue cracks. Therefore, the mold should be slowly cooled after use, otherwise, thermal stress will occur, which will cause the mold to crack and fail.

4. Die casting and maintenance

The mold should be fully preheated before die casting. If the preheating temperature is too high, the temperature of the mold is too high during use, the strength is reduced, and plastic deformation is easy to occur, causing the mold surface to collapse; the preheating temperature is too low when the mold starts to use, the instantaneous surface temperature changes greatly, and the thermal stress is large. Initiation of cracks.