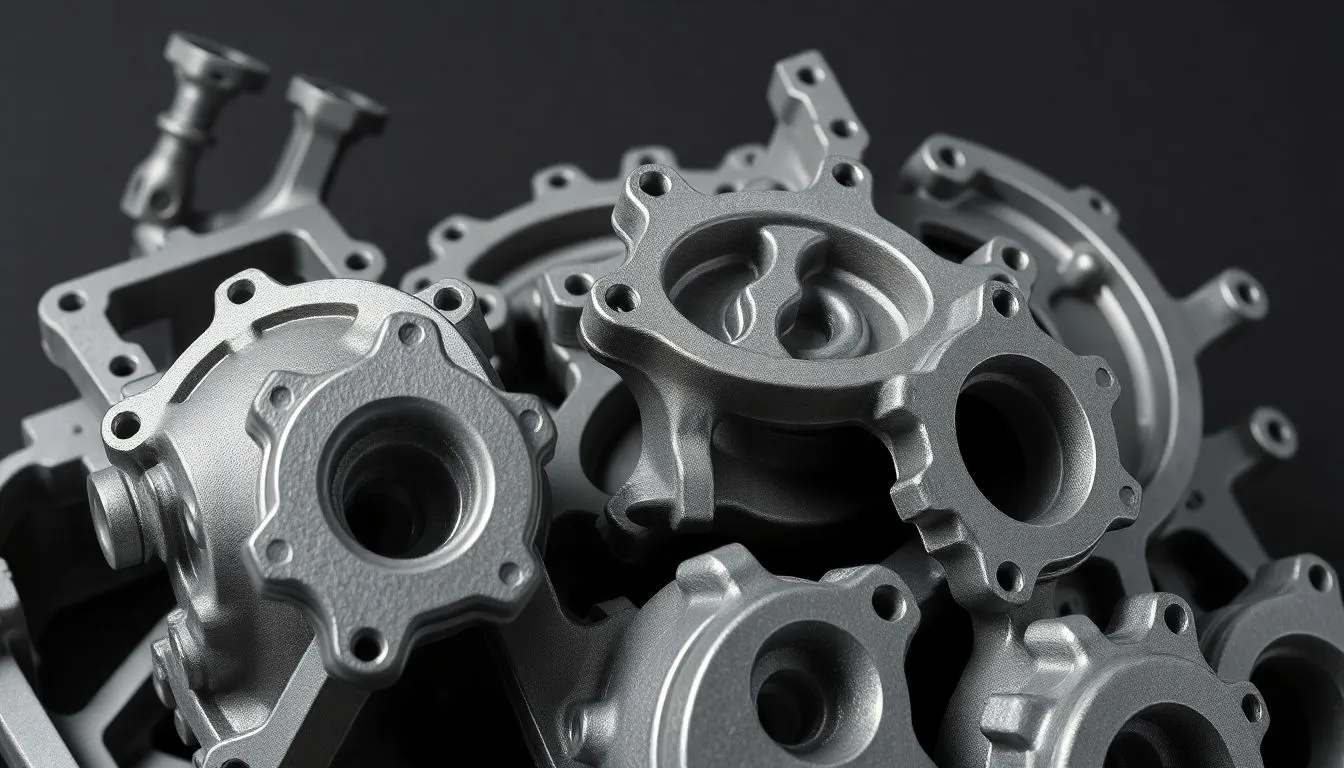

Aluminum die-casting technology is widely used in the automotive and electronics industries due to its unique advantages. The light-weight, high strength, and corrosion resistance of aluminum alloy make it an ideal choice for manufacturing various parts.

In the automotive industry, as energy conservation and emission reduction standards are raised, light-weight has become an important direction for development. Aluminum die-casting parts, with their light-weight, high strength, and relatively low cost, are widely used in key components such as engines, gearboxes, and body structures.

In the electronics industry, aluminum alloy not only provides good electromagnetic shielding performance but also effectively dissipates heat, ensuring the stable operation of electronic devices. For example, the casings of portable devices such as smartphones and laptops often use aluminum alloy materials to achieve both portability and durability.

Furthermore, the high efficiency and precision of the aluminum die-casting tooling process are also important reasons for its widespread use. The die-casting process can produce parts with complex shapes and precise dimensions, and the production efficiency is high, and suitable for large-scale production. This has significant economic implications for the automotive and electronics industries that pursue rapid development and cost reduction.

Therefore, aluminum die-casting technology, with its material characteristics and production efficiency advantages, is widely used in the automotive and electronics industries and will continue to play an important role in these fields.