| Injection Molding Die casting | ||

| Product application | Plastic products | Metal products |

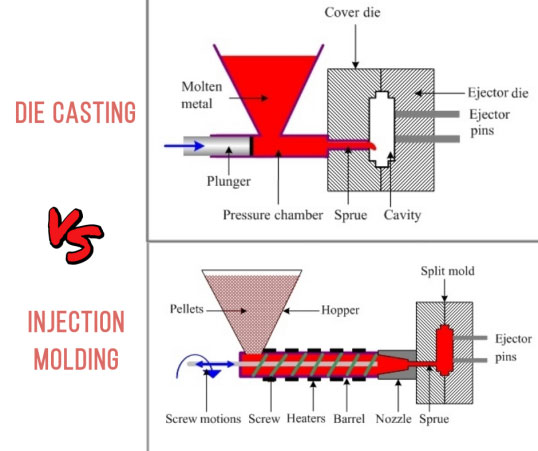

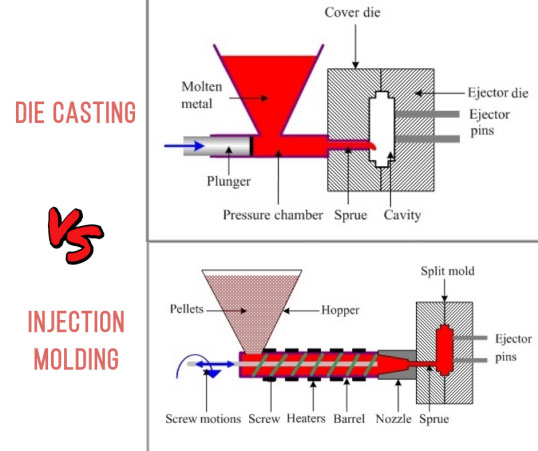

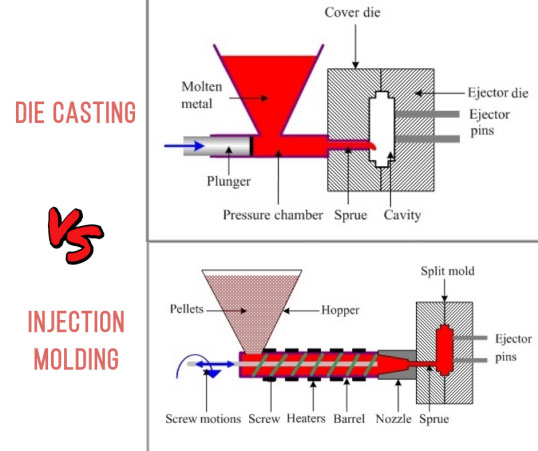

| Process | Injecting a heated and melted material into a mold cavity under high pressure and cooling and solidifying to obtain a molded product | |

| A molten alloy liquid is poured into a pressure chamber, a cavity of a steel mold is filled at high speed, and the alloy liquid is solidified under pressure to form a casting. | ||

| Temperature control | The barrel temperature ,nozzle temperature and mold temperature need to control. | The mold cavity temperature exceeds |

| 700 degrees | ||

| Pressure control | ①The plasticizing pressure depends on the type of plastic used. | Metal liquid fills cavity under pressure, the common pressure is 15-100MPa. |

| ②The injection pressure is based on the pressure applied to the plastic by the top of the plunger or screw (converted from the oil pressure) | ||

| Molding cycle | ①The filling time is about 3-5 seconds. | ①The metal liquid fills the cavity usually at 10-50 m / s, and some can exceed 80 m / s. |

| ②The dwell time is about 20-120 seconds ( special thick parts can be up to 5-10 minutes ) | ② The cavity can be filled in about 0.01-0.2 seconds (depending on the size of the casting). | |

| Feature | ①Production is fast due to the flexibility in the molding process | ①Efficient process with a high degree of accuracy |

| ②Plastic Injection molds can accommodate different plastic or polymer materials | ②No need secondary processing | |

| ③Fillers can be used in plastic molds to increase strength | ③Complicated designs can be easily made | |

| ④Efficient process with very accurate finishes | ③Produces higher-quality products with better tolerance that will last longer | |