The tooling room is also the process equipment room, and various tools used in the manufacturing process, such as tools, fixtures, molds, measuring tools, inspection tools, auxiliary tools, bench tools, station tools, etc.

In engineering and manufacturing, toolroom activity is everything related to tool-and-die facilities in contrast to production line activity.

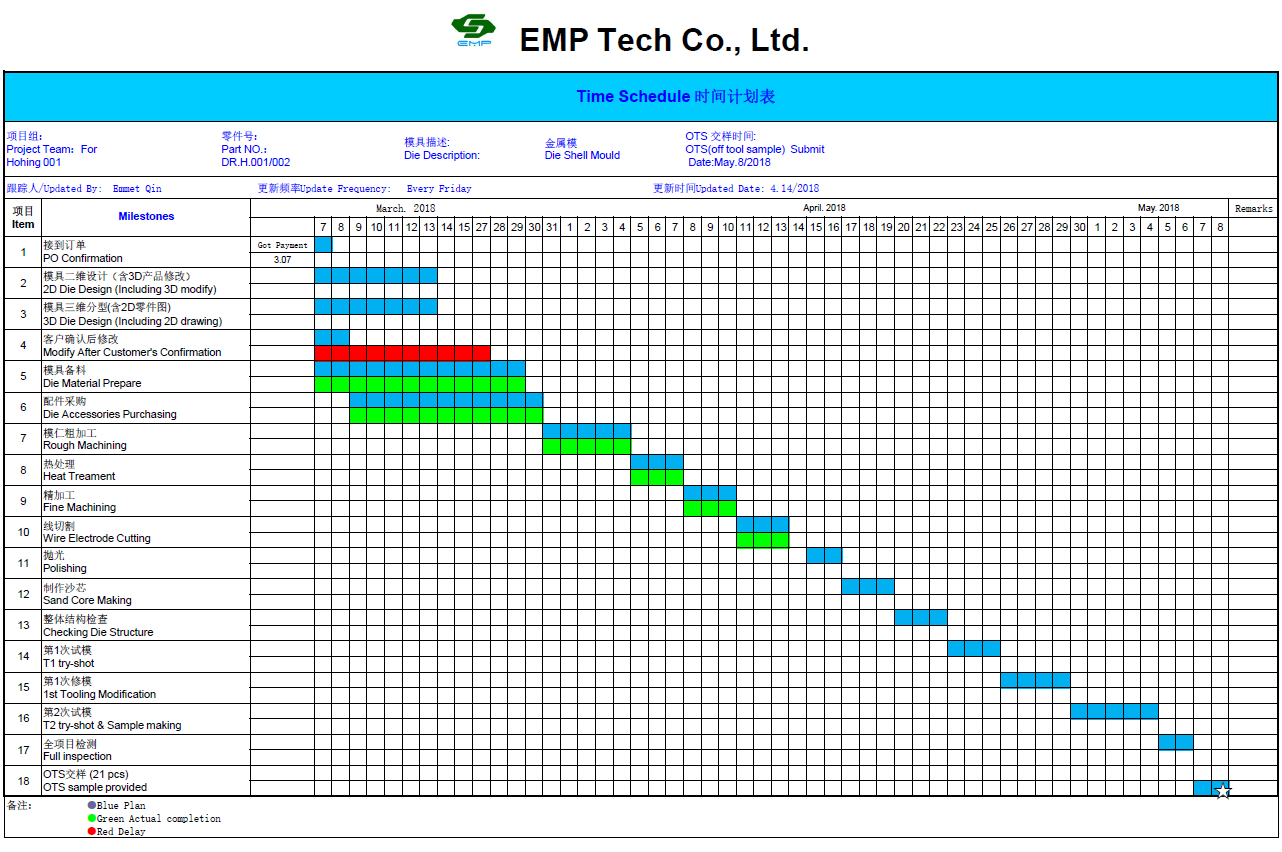

The tooling workshop has various equipment for the manufacturing process, such as tools, fixtures, molds, measuring tools, inspection tools, auxiliary tools, bench tools, station tools, etc. EMP is following each step in developing new tooling per the Gantt schedule as below.

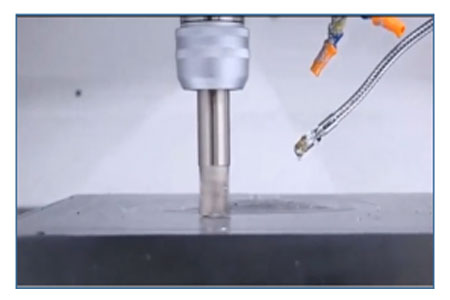

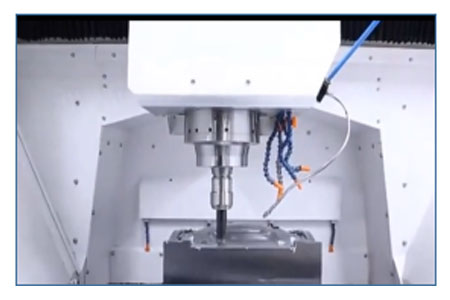

CNC deep hole drilling, micro hole edm drilling, custom drilling, etc.

Cutting aluminum tubing, cutting aluminum plate, cutting aluminum angle, cutting thin aluminum sheet, cutting aluminum bar, cutting aluminum trim, cutting rectangular holes in aluminum, cutting aluminum flat bar, etc.

EDM micro drilling, wire EDM aluminum, etc.

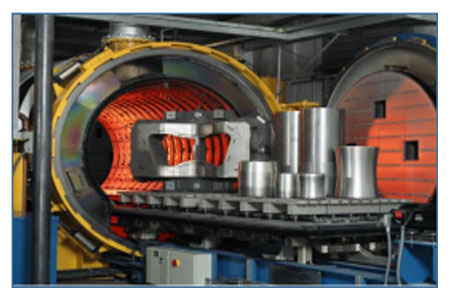

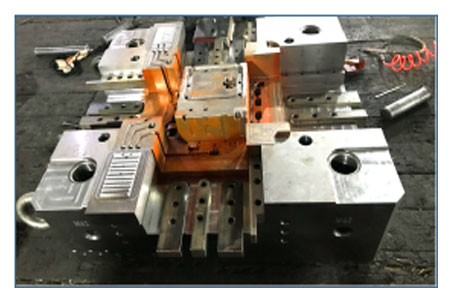

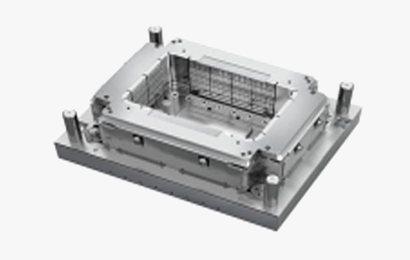

Die casting mold is a kind of tool for casting metal parts, which is used to complete the die casting process on a special die casting mold forging machine. The basic process of die cast tooling is: the liquid metal is first cast at low or high speed and filled into the cavity of the die. The die has a movable cavity surface, which is pressed and forged with the cooling process of the liquid metal. It not only eliminates the shrinkage defects of the blank, but also makes the internal structure of the blank reach the forged broken grain. The comprehensive mechanical properties of the blank have been significantly improved.

The design and manufacture of the die cast tooling from EMP, one of the most professional aluminium die casting manufacturers in China, are in line with international quality standards. Tooling room uses CAD/CAM, CATIA V5, UG, Pro-E technology, in-house tooling design/manufacturing, finite element method and moldflow simulation, etc.

EMP owns a professional die casting mold factory, we offer precision die casting service and various custom services such as custom drilling and custom aluminum machining. To check more about die casting tool design, please contact us now!

The fixture used to quickly, conveniently, and safely mount a workpiece during any process in the whole process. For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc.

The mold is a device that defines the shape and size of the production object.

The cutlery are used in machine construction and are basically used to cut metal materials.

The check tool is an instrument that is inspected during production.

The clamp is composed of a positioning element, a clamping device, a coupling element, a tool setting or guiding element, other devices, and a clamp.

When machining a workpiece on a machine tool, in order to achieve the technical requirements of the dimensions of the workpiece, the geometry, and the accuracy of the mutual position of the other surfaces, the workpiece must be assembled and clamped before machining. Its role is to ensure processing accuracy, increase productivity, expand the scope of machine tools, and reduce the labor intensity of workers.