Porosity defects, such as gas entrapment and shrinkage voids, are common challenges in aluminum die casting, impacting the quality of EV components like battery enclosures, motor controller housings, and transmission cases. High vacuum die casting (HVDC) is an advanced manufacturing technique that significantly reduces these defects, ensuring high-quality, durable parts for electric vehicles.

Understanding Porosity in Die Casting

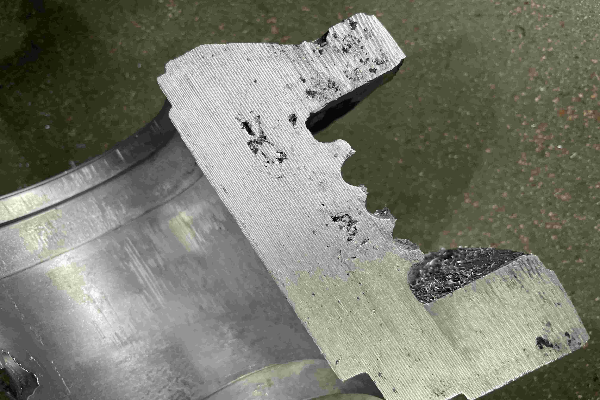

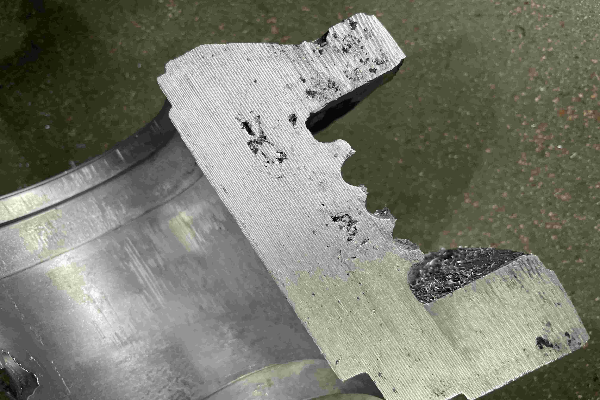

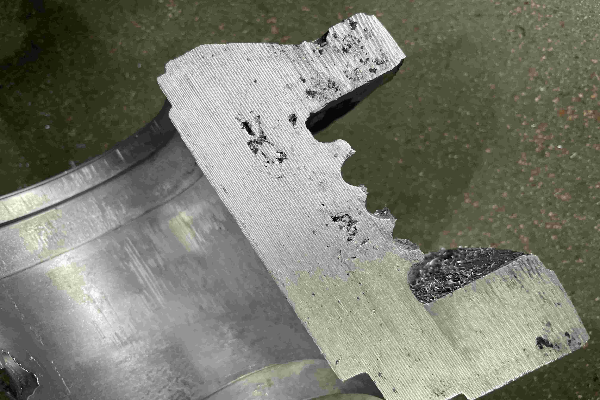

Porosity occurs when gases, typically air or mold release agents, become trapped in the molten aluminum during the die-casting process, forming voids or cavities in the final part. These defects weaken components, reduce fatigue resistance, and compromise performance in critical EV applications like powertrain housings. Shrinkage porosity, caused by uneven cooling, can also create internal voids, affecting structural integrity. High vacuum die casting addresses these issues by optimizing the casting environment.

The Role of High Vacuum Die Casting

High vacuum die casting involves evacuating air from the die cavity and shot sleeve before injecting molten aluminum. By creating a near-vacuum environment, typically below 50 mbar, HVDC minimizes air entrapment, reducing gas porosity. This process is particularly effective for complex EV components, such as battery enclosures and inverter housings, where precision and strength are critical. The vacuum system removes gases efficiently, ensuring a denser, more uniform microstructure in the cast part.

Key Mechanisms for Porosity Reduction

Air Evacuation: HVDC systems use powerful vacuum pumps to remove air and residual gases from the mold cavity before injection. This prevents gas entrapment in components like motor controller housings, resulting in fewer voids and improved mechanical properties.

Controlled Filling: The vacuum environment allows for smoother, more controlled molten metal flow, reducing turbulence that can trap air. This is essential for intricate parts like transmission cases, ensuring consistent density and surface quality.

Minimized Shrinkage: By maintaining pressure during solidification, HVDC reduces shrinkage porosity. The process ensures uniform cooling, preventing voids in thick-walled sections of EV structural brackets or battery enclosures.

Enhanced Alloy Performance: HVDC is compatible with high-strength aluminum alloys like ADC12, which are widely used in EV manufacturing. The low-porosity castings enhance fatigue resistance, critical for powertrain components.

Benefits for EV Manufacturing

High vacuum die casting produces defect-free components that meet the stringent IATF 16949 standards for automotive applications. For example, low-porosity motor controller housings improve thermal conductivity, enhancing EV battery efficiency. The process also supports lightweighting, as denser aluminum parts maintain strength without added material, extending vehicle range. Additionally, HVDC’s efficiency reduces scrap rates, aligning with sustainable manufacturing goals.

Conclusion

High vacuum die casting is a game-changer for producing high-quality aluminum components for electric vehicles. By minimizing gas and shrinkage porosity, it ensures durable, lightweight parts like battery enclosures and transmission housings, meeting the EV industry’s demand for performance and sustainability.