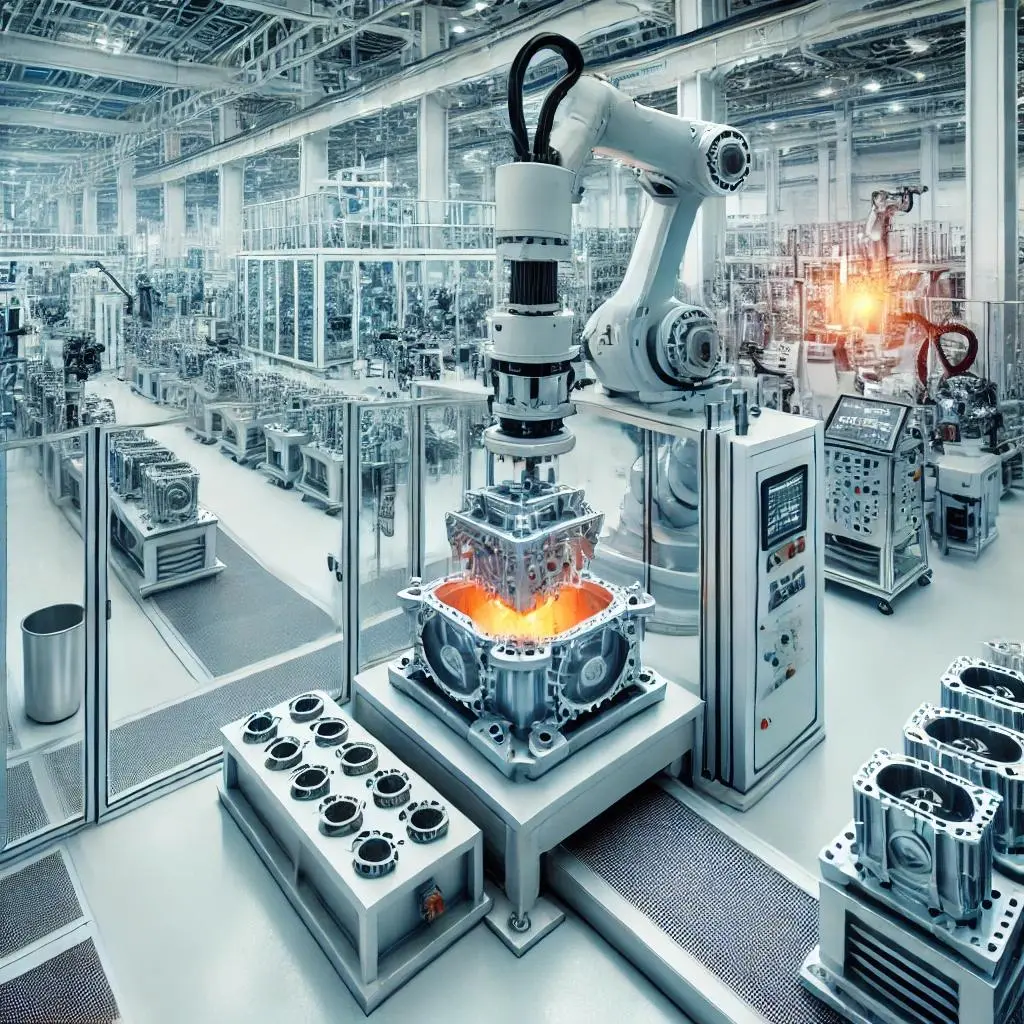

The full name of die casting is press die casting. It is a precision casting method in which a molten metal liquid is poured into a steel mold and then cooled to shape by applying high pressure.

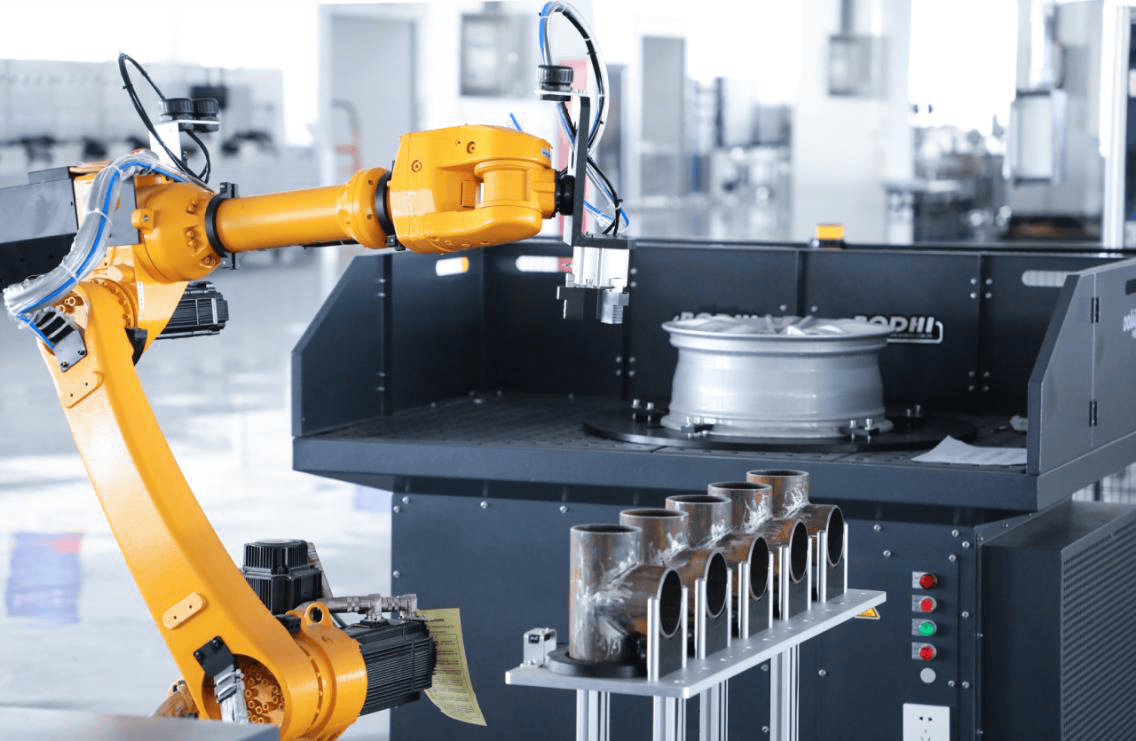

Metal products are mainly produced by three processes: milling, sheet metal forming welding and casting. Among them, casting mainly produces the internal structure of complex, difficult to use sheet metal forming or machine tool milling does not have the economy of the parts. Casting is mainly divided into sand casting and special casting two categories, die-casting belongs to the category of special casting.

Die casting is suitable for casting metal parts (aluminum, zinc, copper, etc.) with complex structure, thin walls, high precision requirements and lower melting point than steel. As a kind of near-net forming metal thermal processing molding technology with almost no cutting, its products have many advantages such as precision, light weight and beautiful, and are widely used in many industries such as automobile, home appliance, aviation and machinery.

Die casting has the advantages of high efficiency and high precision, but it is limited by the melting point of the mold and mainly produces aluminum alloy and magnesium alloy. Compared with gravity casting, which uses quartz sand as the casting mold, die casting has the following advantages.

1. the mold can be used repeatedly.

2. rapid molding and continuous production can be achieved through the cooling system in the mold.

3. The pressure applied to the molten metal during cooling ensures better stress strength of the part.

4. Precise internal dimensions of the metal mold, allowing for precision casting.

Although die casting is efficient, it can only manufacture metals with lower melting points than steel because the mold materials are all made of steel. At present, the base materials used in die-casting industry are mainly aluminum alloy, zinc alloy, copper alloy, magnesium alloy and other alloy materials, among which aluminum alloy has the highest proportion.