Introduction to EV Parts Manufacturers

As the electric vehicle (EV) market continues to surge, the demand for specialized EV parts manufacturers is at an all-time high. These manufacturers play a critical role in supplying the essential components that make EVs more efficient, durable, and sustainable. Among the vast array of parts, die-cast EV parts like motor housings and battery cases stand out due to their high performance and lightweight properties.

What is EV Parts Manufacturing?

EV car parts manufacturing involves producing components specifically designed for electric vehicles. These parts range from powertrains to body structures, all of which must meet stringent quality standards to ensure optimal vehicle performance.

Importance of Quality Components in Electric Vehicles

Electric vehicles are designed for efficiency and durability. The quality of the parts directly impacts factors like energy consumption, vehicle longevity, and overall performance. This is why EV parts manufacturers focus heavily on innovation and quality.

The Role of Die-Casting in EV Parts

What is Die-Casting?

Die-casting is a manufacturing process that involves injecting molten metal into a mold to create precise and durable components. In the context of EVs, die-casting is used to produce parts that are both lightweight and strong, which is essential for improving vehicle efficiency.

Why Die-Casting is Crucial for EV Parts Production

Die-casting allows for the production of complex shapes with high accuracy, which is important in manufacturing critical EV components. The process also reduces the number of individual parts required, simplifying assembly and lowering production costs. Custom EV parts from die casting China companies.

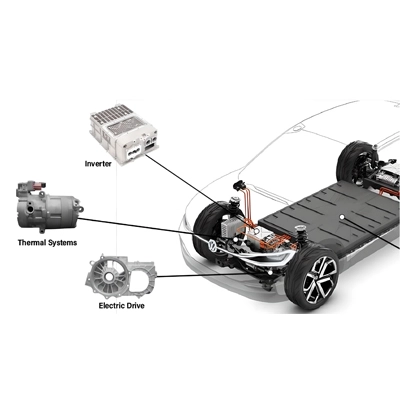

Key EV Parts Produced Through Die-Casting

Motor Housings

One of the most important die-cast components in electric vehicles is the motor housing. This part protects the electric motor from external elements and provides structural integrity.

EV Battery Cases

Battery cases are another key component in EVs. These die-cast parts offer protection to the battery pack, which is the most expensive and critical part of the vehicle.

Inverter Housings

Inverter housings, which protect the electronics that manage the power flow in EVs, are also often produced using die-casting for their durability and precision.

Other Lightweight Structural Components

Beyond motor housings and battery cases, die-casting is used to produce various structural parts that contribute to the overall strength and lightweight nature of electric vehicles.

Motor Housing: A Key Die-Cast Component

Why Motor Housing is Critical for EVs

Motor housings provide the necessary protection and cooling for electric motors, ensuring they function optimally even under high stress and extreme conditions.

Benefits of Die-Casting in Motor Housings

Die-casting allows for a lightweight yet robust motor housing, which improves the efficiency of the electric motor and reduces overall vehicle weight.

EV Battery Cases: Protecting the Heart of EVs

Battery Safety and Durability

The battery is the heart of an electric vehicle, and the case must offer both protection and thermal management to ensure safety and performance.

Die-Casting for Lightweight and Strong Battery Cases

Die-cast battery cases are designed to be lightweight while providing the structural strength needed to protect the battery from impacts and environmental factors.

The Benefits of Using Die-Cast Components in EVs

Weight Reduction and Improved Efficiency

Die-casting helps reduce the overall weight of EV parts, which is crucial for improving the vehicle's energy efficiency and range.

Cost Efficiency in Large-Scale Production

For manufacturers, die-casting offers a cost-effective solution, especially when producing EV parts at scale, thanks to its repeatability and precision.

Better Thermal Management

Die-cast components can be designed to improve thermal management, which is particularly important for parts like motor housings and battery cases that generate heat.

Challenges in Die-Casting for EV Parts

Material Selection

Choosing the right material is crucial for die-casting, as it impacts the performance and durability of the EV part.

Design Complexities

Designing die-cast components for EVs can be complex due to the intricate shapes required and the need to maintain structural integrity.

Production Scalability

As the demand for electric vehicles grows, manufacturers face the challenge of scaling up die-casting production while maintaining quality and efficiency.

Innovations in Die-Casting for EV Manufacturing

Advances in Material Technology

New materials, such as advanced aluminum alloys, are being developed to improve the strength and weight of die-cast EV parts.

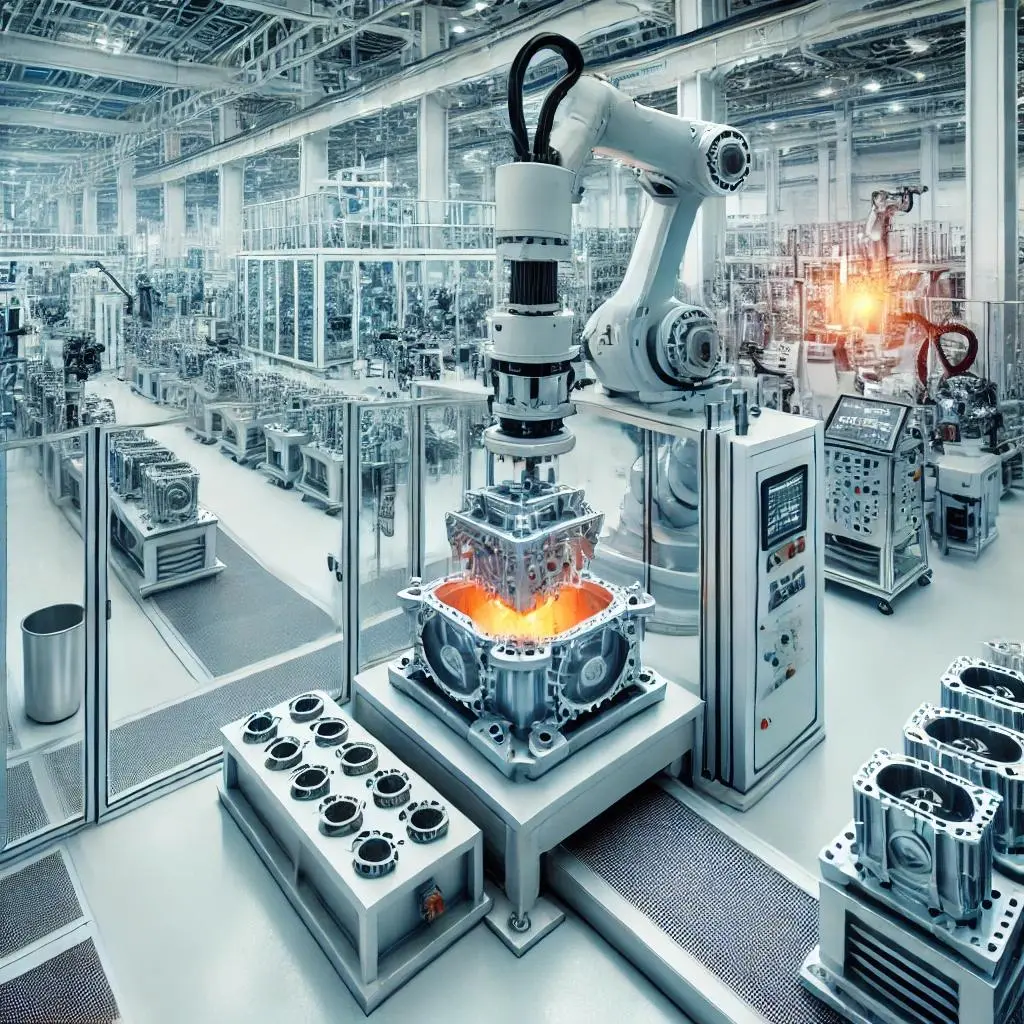

New Die-Casting Techniques for Complex Parts

Innovative die-casting techniques, such as multi-slide die-casting, are allowing manufacturers to create more complex and precise parts for electric vehicles.

Sustainability and Environmental Impact

The die-casting industry is also focusing on reducing its environmental impact by developing more energy-efficient production processes and using recycled materials.

Leading EV Parts Manufacturers Focusing on Die-Casting

Major Global Players

Companies like Tesla, BYD, and BMW are heavily investing in die-cast parts for their electric vehicles, driving innovation in the sector.

Specialized EV Parts Manufacturers

There are also specialized manufacturers that focus solely on producing aluminum die casting auto parts, providing custom solutions for automakers.

Key Regions for EV Parts Production

Regions like China, Germany, and the United States are leading the way in die-cast EV parts production, thanks to their advanced manufacturing infrastructure and focus on innovation.

Future Trends in Die-Casting EV Parts

Adoption of New Materials Like Magnesium and Aluminum Alloys

The future of die-casting for EVs lies in the adoption of even lighter materials, such as magnesium and advanced aluminum alloys, to further reduce vehicle weight.

Automation in Die-Casting Processes

Automation is becoming more prevalent in die-casting, enabling manufacturers to produce EV parts with higher precision and at a faster rate.

Impact of Electric Vehicle Growth on Die-Casting

As the EV market continues to grow, the demand for high-quality, die-cast components will increase, pushing manufacturers to innovate and scale up production.

Conclusion

Die-casting plays a crucial role in the production of essential electric vehicle parts, from motor housings to battery cases. Its ability to create lightweight, strong, and precise components makes it invaluable for the future of EV manufacturing. As technology continues to advance, so will the methods and materials used in die-casting, ensuring that electric vehicles become more efficient, sustainable, and cost-effective.

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China