In the dynamic realm of automotive manufacturing, innovations that enhance efficiency while maintaining structural integrity are worth their weight in gold. One such groundbreaking technique making waves in the industry is friction welding, specifically when applied to aluminum components. This blog delves into the fascinating world where efficiency is unleashed through the friction welding aluminum in the automotive sector.

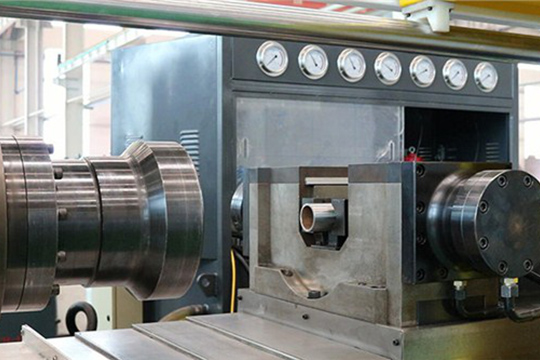

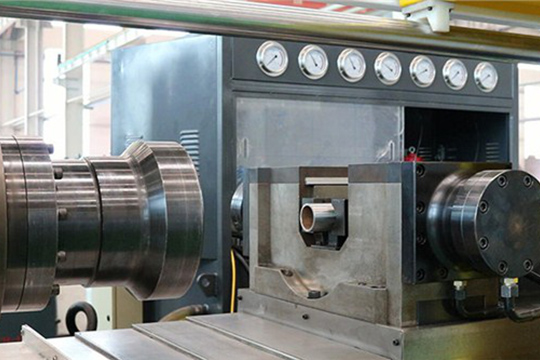

At its core, friction welding aluminum is a solid-state welding process that generates heat through the mechanical friction between two surfaces. When applied to aluminum, this process creates a seamless bond, eliminating the need for traditional fusion methods like arc welding. The absence of molten material not only expedites the welding process but also preserves the structural integrity of the aluminum, a critical factor in the demanding environment of automobiles.

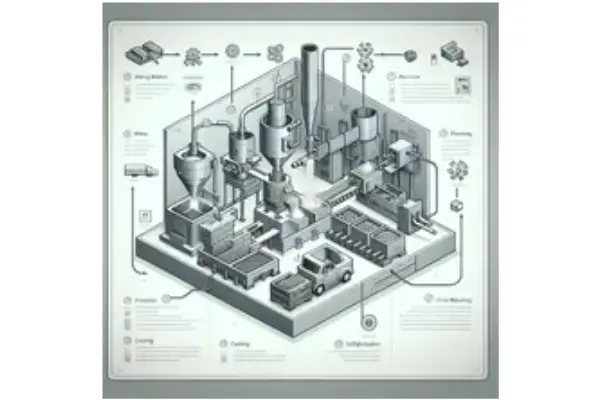

Friction welding aluminum presents a paradigm shift from conventional welding techniques in the automotive industry. The elimination of filler material, reduced heat-affected zones, and superior joint strength are just a few of the advantages that make friction welding aluminum an attractive choice. The efficiency gains from quicker welding times and enhanced material properties contribute to cost savings and bolster the overall sustainability of automotive manufacturing processes.

Aluminum's inherent lightweight properties make it a preferred material for automotive design aiming for fuel efficiency. Friction welding aluminum takes this a step further by allowing manufacturers to join aluminum components with precision and strength. The result is a reduction in the overall weight of the vehicle without compromising structural integrity, contributing significantly to fuel economy and sustainability.

In the pursuit of safer and more durable vehicles, structural integrity is paramount. Friction welding aluminum ensures a robust bond between aluminum components, enhancing the overall strength of the vehicle. This not only improves crash performance but also contributes to the longevity of the automobile, aligning with the industry's focus on safety and quality.

As automotive manufacturers continue to push the boundaries of innovation, the combination of friction welding and aluminum opens doors to new possibilities. From electric vehicles to autonomous cars, the efficiency and reliability of friction-welded aluminum components lay the foundation for the next generation of automotive engineering.

In conclusion, the friction welding aluminum in the automotive industry signifies a leap forward in efficiency and performance. From the shop floor to the open road, this dynamic duo is reshaping how vehicles are constructed, emphasizing speed, strength, and sustainability. As automotive engineering evolves, the impact of friction welding aluminum promises to be a driving force in the relentless pursuit of efficiency in the automotive sector.