Die-casting molds, die-casting machines, and die-casting materials are the three major factors of die-casting production. Only high-quality molds can produce stable and efficient casting with good quality. Studying the factors that affect the performance and service life of molds is beneficial to improve the quality of castings and reduce the economic losses caused by early scrap of molds. Generally speaking, the factors that affect the performance and service life of die-casting molds include mold materials, mold design and manufacturing, surface treatment technology, and specific use of molds.

The performance and service life of die-casting molds are closely related to the material of the molds. Good-die casting mold manufacturing materials generally have the following characteristics: good cutting and forging properties; high wear resistance and corrosion resistance; high strength and red hardness, heat resistance, oxidation resistance, impact toughness, and tempering stability at high temperatures; good thermal conductivity and fatigue resistance; small thermal expansion coefficient; small thermal treatment deformation rate and good quenching permeability. In addition to the temperature of the cast metal and the type of cast metal, the selection of mold materials should also consider the impact and wear of each component of the die-casting mold caused by the cast metal. The higher the temperature, the higher the material's thermal fatigue performance and high-temperature performance should be. Parts with severe wear should have higher hardness. The increasingly demanding working conditions of die-casting molds continually increase the requirements for metallurgical quality, performance, and service life of mold materials, especially the purity and isotropy of materials. Some high-alloy, high-quality, and optimized mold materials continuously appear, which in turn promotes the development of the die-casting industry.

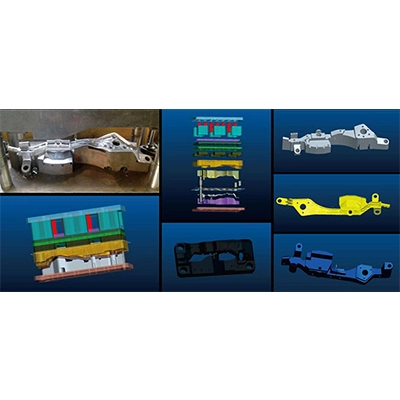

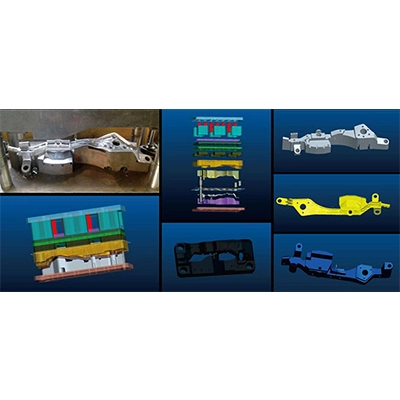

Reasonable mold design is an important prerequisite for prolonging the service life of die-casting molds. Reasonable wall thickness and cooling channel design can ensure the strength and thermal balance of the mold. In die-casting mold design, special attention should be paid to parts with stress concentration and large wear. The selection and matching of the precision of each part need to be reasonable: if the clearance is too large, the heat will not conduct well, resulting in thermal fatigue damage; if the clearance is too small, extrusion force and tensile stress will be generated. Internal stress is easy to generate during mold manufacturing, which has a great influence on the service life of the mold. Therefore, it should avoid producing and eliminating internal stress as much as possible during the manufacturing and processing of the mold. For example, after rough machining, tempering should be used to eliminate stress, and an electric pulse should be used instead of an electric spark to reduce the surface tensile stress of the mold.

Through rigorous and reasonable technical treatment on the surface of the die-casting mold, its performance and service life can be greatly improved. The surface treatment technology of die-casting molds can generally be divided into three categories: improvement of traditional heat treatment technology, surface modification technology such as surface laser treatment technology, and coating technology.

Choosing a reasonable die-casting process and maintenance is crucial to the service life of the mold. A large part of the damage to the mold is caused by improper use and lack of scientific maintenance. Firstly, special attention should be paid to the temperature control of the mold. Preheating the mold before production and maintaining an appropriate temperature range during production can prevent surface cracks and even cracks caused by excessive temperature gradients inside and outside the mold cavity. Secondly, high-quality die-casting releasing agents should be used, and their thickness should be moderate. They should uniformly coat the mold surface to play a crucial role in protecting the mold material. Finally, to reduce the accumulation of thermal stress and avoid a crack in die-casting molds, it is necessary to adopt technologies such as tempering to eliminate thermal stress regularly.

The materials of die-casting molds, mold design, and manufacturing, mold surface treatment technology, and mold use comprehensively affect the performance and service life of the mold. By comprehensively considering these factors and taking effective measures, the performance of die-casting molds can be effectively improved, and the service life of die-casting molds can be prolonged.