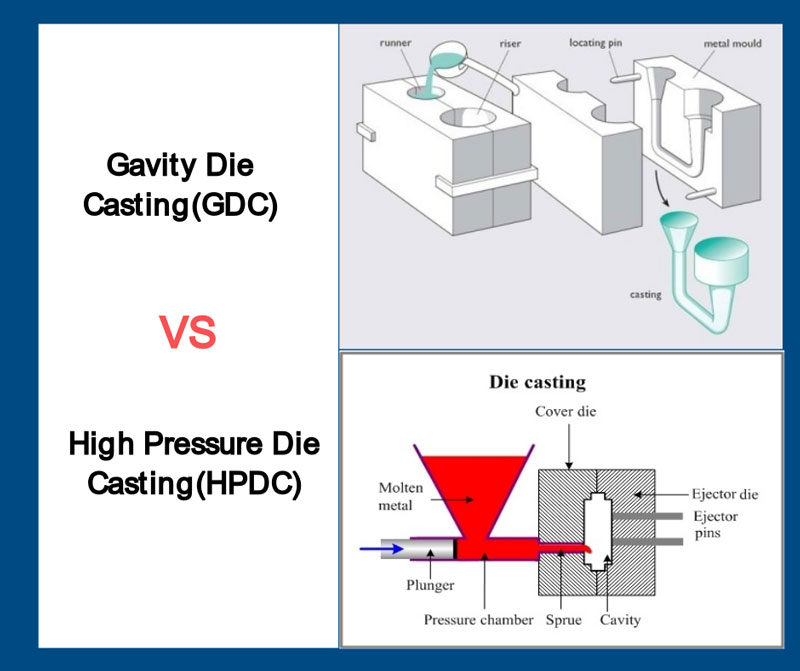

Casting Process | GDC | HPDC |

Explanation | A casting method in which liquid metal is poured into a mold made of metal using the gravity of the earth, and solidify under the action of gravity to form a casting. | A casting method in which a 660-degree liquid aluminum alloy is poured into the pressure chamber of a die-casting machine to fill a mold cavity under high pressure and high speed, and then come into form under high pressure to obtain a casting part. |

Advantage | 1) There are few pores in the casting, which can be heat-treated, and the strength of the product can be greatly improved after heat treatment. 2) Long mold life and low mold cost 3) Higher elongation 4) The process is relatively simple. | 1) Good product quality 2) High productivity and more use of die casting molds 3) Good economic benefits |

Disadvantage | 1) Slow filling and low production efficiency, leading to higher product costs. 2) Relying on liquid self-weight molding, the product has low density and slightly lower strength. 3) The surface finish of the product is not high, and the casting product is likely to form a blast-like pit on the surface after cooling and shrinking. 4) Not suitable for the production of thin-walled parts | 1) The mold structure is complex, the manufacturing cost is high, and the preparation cycle is long. 2) The die-casting speed is high, the gas in the cavity is difficult to exhaust completely, and the metal mold solidifies quickly in the mold, and the possibility of shrinkage is small, so that the casting is prone to produce small pores and shrinkage. 3) The plasticity of the die-casting parts is low, so it is not suitable to work under shock load and vibration. |

Application | Suitable for large wall thickness products, such as steering knuckles, control arms and other chassis safety parts. | 1) Disc, round cover, ring type-pump casing cover, bearing retainer, steering wheel, etc. 2) Multi-cavity cylinders, shells-cylinder blocks, cylinder heads, oil pumps. |