Aluminum die casting is a popular manufacturing process used to produce complex, high-precision parts in large quantities. These parts are used in a variety of industries, including automotive, aerospace, and electronics, where strength and durability are crucial factors. But just how strong are aluminum die casting parts? In this article, we'll explore the strength of aluminum die casting parts and what factors affect their strength.

The strength of aluminum die casting parts depends on several factors, including:

Aluminum Alloy: The choice of aluminum alloy used for die casting can greatly affect the strength of the final product. Different aluminum alloys have different properties, such as strength, ductility, and corrosion resistance, which can impact the strength of the part.

Design: The design of the part can also affect its strength. Parts with thicker walls and fewer sharp corners tend to be stronger than parts with thin walls and sharp corners.

Heat Treatment: Heat treatment is often used to enhance the strength of aluminum die casting parts. Heat treatment involves heating the part to a specific temperature and then cooling it down in a controlled manner. This process can increase the strength and durability of the part.

Manufacturing Process: The manufacturing process used to produce the part can also affect its strength. Proper process control and quality assurance measures must be in place to ensure that the part is produced to the desired strength.

The strength of aluminum die casting parts varies depending on the specific application and the factors listed above. However, in general, aluminum die casting parts are known for their high strength-to-weight ratio. Aluminum alloys used for die casting typically have a tensile strength of 40,000-60,000 psi, with some high-performance alloys having even higher strength.

In addition to their high strength, aluminum die casting parts also offer excellent corrosion resistance, good thermal conductivity, and are lightweight, making them ideal for a wide range of applications.

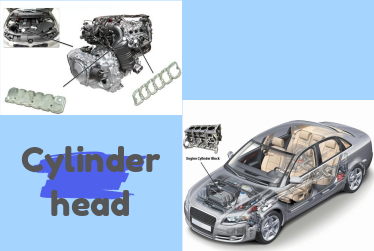

Automotive: Aluminum die casting parts are commonly used in automotive applications, such as engine blocks, transmission cases, and suspension components.

Aerospace: The aerospace industry also uses aluminum die casting parts for applications such as aircraft engine components and structural parts.

Electronics: Aluminum die casting parts are used in a range of electronic applications, including heat sinks, enclosures, and connector housings.

Medical: The medical industry uses aluminum die casting parts for applications such as medical equipment housings and surgical instruments.