Overview: The cylinder head is made of cast iron or aluminum alloy. It is the installation base of the valve mechanism and the sealing cover of the cylinder. The good cylinder and the top of the piston from the combustion chamber.

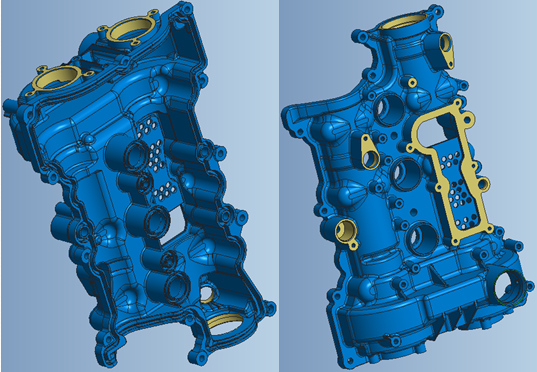

Structure: The cylinder head is a box-shaped part with a complex structure. Its structure depends on the cooling method of the engine, the number of valves per cylinder, the position of the camshaft, the intake and exhaust ducts and the shape of the combustion chamber. The cylinder head has a valve seat, a valve guide hole, a cylinder head bolt hole, a lubricating oil passage hole leading to the valve rocker arm, and intake and exhaust passages.

Structural features:

1. Water-cooled cylinder heads are divided into integral type, split type and single type.

2. Air-cooled engines are all single-piece cylinder heads.

3. The integral cylinder head has a compact structure, which can shorten the centre distance of the cylinder.

4. The single-piece cylinder head has high rigidity and is superior in spare parts storage, repair and manufacturing.

Function:

a. Provide engine lubricating oil refuelling channel to shield the cylinder head and valve mechanism to ensure that oil and gas do not leak

b. Separate the lubricating oil from the combustible mixture

c. Provide a fixed position for the camshaft position sensor, ignition coil, wiring harness and other parts

d. Reduce engine noise and vibration.

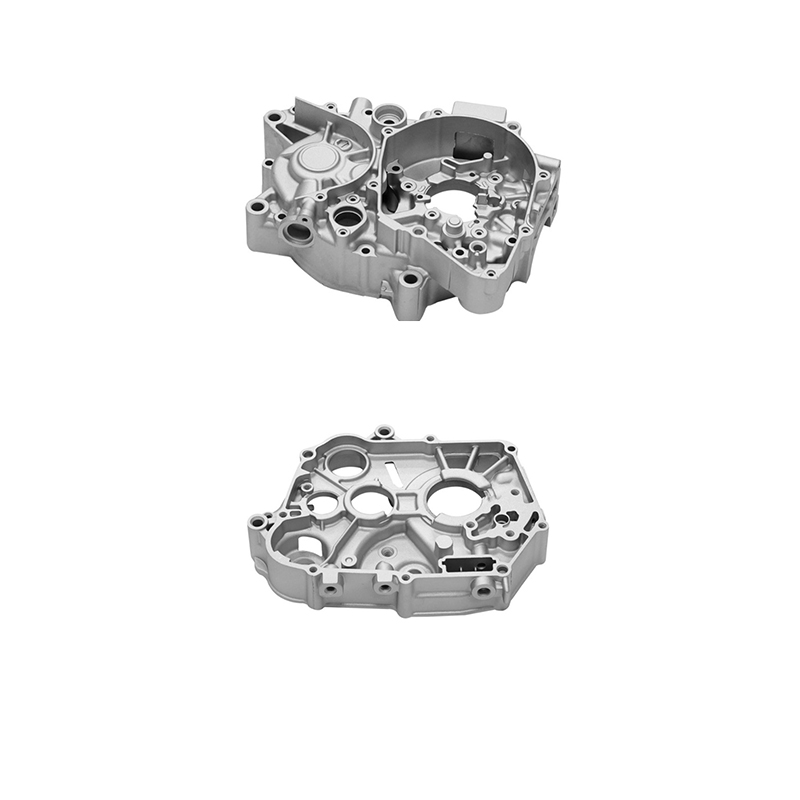

Aluminum alloy meets the requirements of cylinder head cover, chain cover, oil pan, and other engine parts working in harsh environments due to its lightweight, high strength, good heat dissipation, and corrosion resistance. It has become the most widely used in automobiles. One of the alloy materials. The aluminum alloy must be purified, refined, refined, and altered before die-casting so that its mechanical properties and quality can reach consistency and stability.