Tesla’s recent price cuts have sparked widespread attention, with many curious about the company’s strategies for reducing costs while achieving impressive production efficiency. Tesla claims it can produce a car every 45 seconds in its Texas factory, and the Shanghai factory operates even faster, achieving a car every 38 seconds on average. This efficiency is attributed to Tesla’s groundbreaking one-piece die-casting manufacturing technology. Let’s dive into how this innovative approach is reshaping the automotive industry.

Casting allows for intricate designs, making it a vital method in automotive manufacturing. It is broadly classified into two categories: gravity casting and high-pressure casting.

BMW utilizes a similar gravity casting technique for its modular engines, using an aluminum alloy known as AlSiMgCu0.5. This material undergoes advanced heat treatment to enhance its strength, a patented process involving high-temperature solid solution treatment followed by rapid quenching.

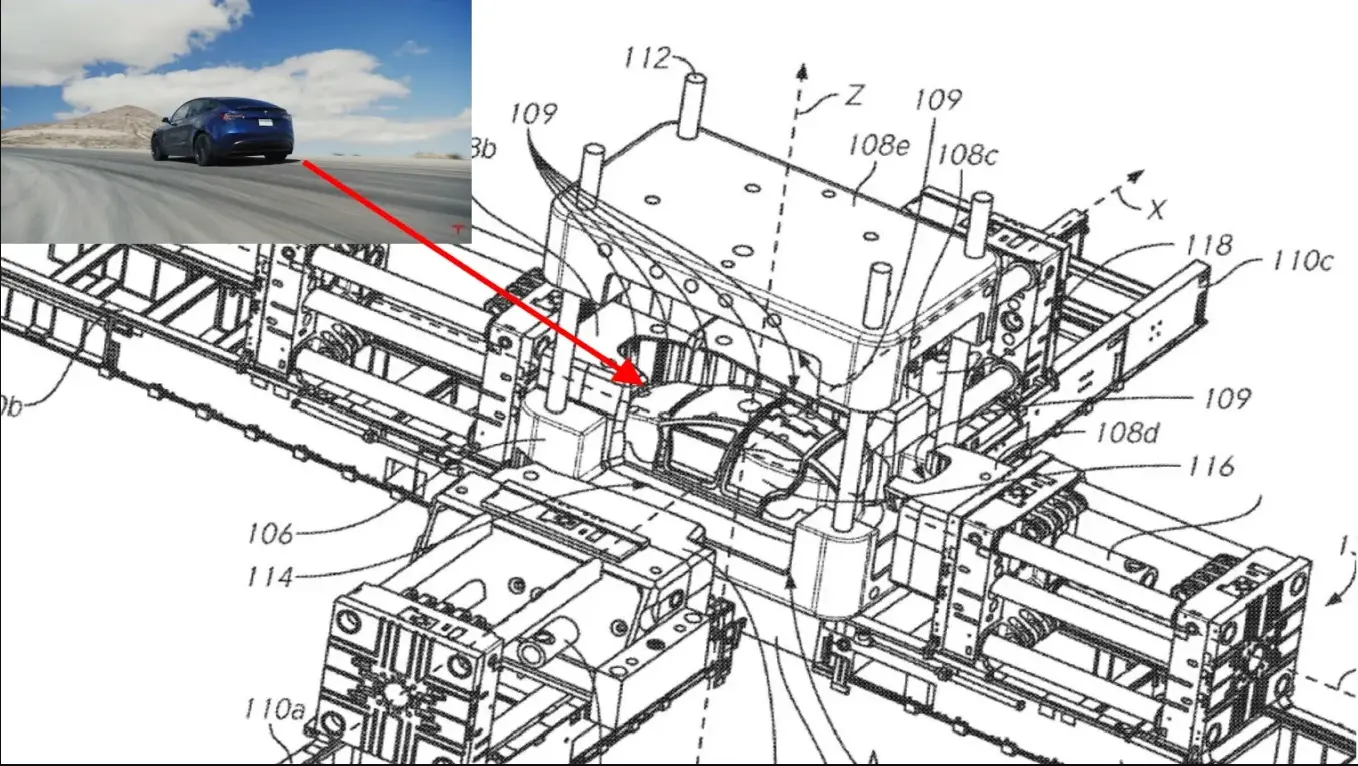

High-pressure casting, commonly referred to as die casting, involves injecting molten aluminum into molds under high pressure. This method is faster and more efficient than gravity casting. One-piece die casting, in particular, is transforming the way vehicles are manufactured.

Reduced Weight: Components are up to 10% lighter, improving electric vehicle range by 14%.

Simplified Production: A reduction of 370 parts streamlines assembly processes.

Increased Automation: Fewer components and weld points enhance production efficiency and automation.

For example, Tesla’s Model Y rear lower body features an integrated die-casting process that eliminates 70 parts. An advanced version further reduces 171 parts and 1,600 weld points, bringing the total weld points of Tesla vehicles to around 50.

In contrast, Tesla’s one-piece die-casting reduces the need for welding and riveting, significantly increasing efficiency. This process not only lowers production costs by 40% but also accelerates the manufacturing timeline.

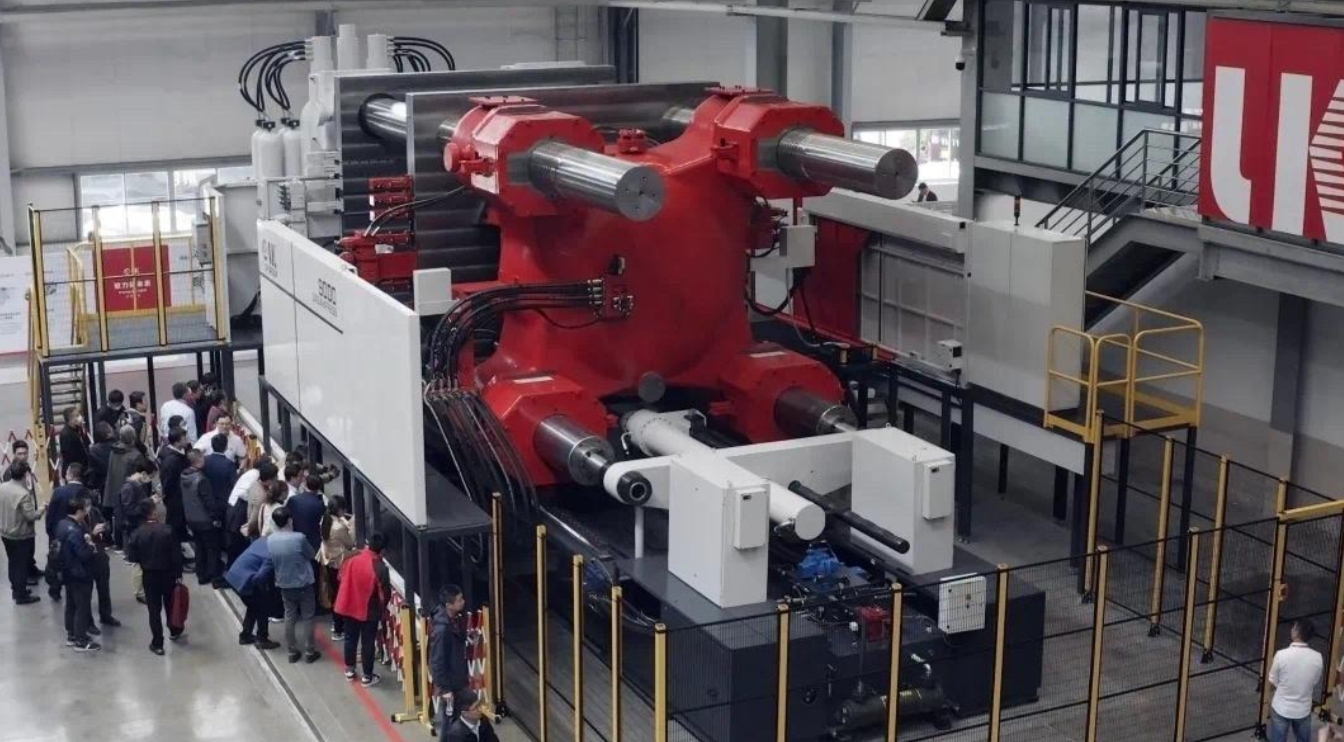

Despite its advantages, one-piece die-casting presents technical challenges. The key lies in the high-pressure equipment, such as Tesla’s 6,000-ton and 9,000-ton Giga Press machines developed by Lijin Technology. These machines enable Tesla to maintain its ambitious production targets of one car every 30 seconds.

Enhancing Sustainability: Lighter vehicles consume less energy, contributing to environmental goals.

Simplifying Supply Chains: Fewer components mean streamlined logistics and reduced dependency on suppliers.

Driving Innovation: Tesla’s success encourages other manufacturers to explore advanced manufacturing methods.