In recent years, the emergence of new technologies and new processes to make die-casting industry is facing a new round of transformation and upgrading, new energy vehicles to die-casting technology, complex thin-walled and ultra-large die-casting structural parts put forward higher requirements.

EMP Tech Co., Ltd. is mainly engaged in the business of new energy auto parts products, the company is committed to the research, development and manufacture of auto parts.We have the latest intelligent die-casting and machining equipment at home and abroad.We help our customers to realize the light weight of the whole vehicle through high pressure die-casting process of aluminum alloy material.

The company currently uses large die-casting machinery Bühler, UBE, ITALPRESSE, IDRA S.R.L, YIZUMI, LK TECH and other brands 350T-4400T die-casting machine nearly 90 sets, the following two examples to introduce.

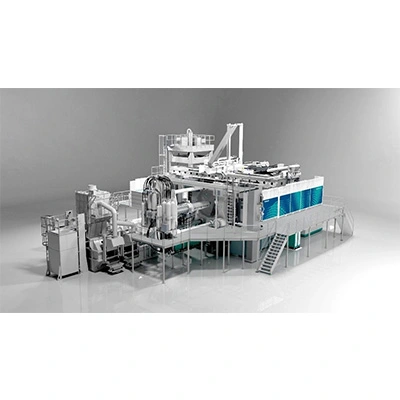

YIZUMI Die-casting Machine

2500Tons

YIZUMI 2500Tons Die-casting Machine Production Capability | ||||

Productiveworkinghours (H) | ProuductionTakt (s) | Productivedays (day) | ||

22 | 113 | 22 | 28 | |

Capacity(pcs/day) | Capacity(pcs/month) | |||

700 | 15400 | 19600 | ||

Capacity(pcs/year) | 184800 | 235200 | ||

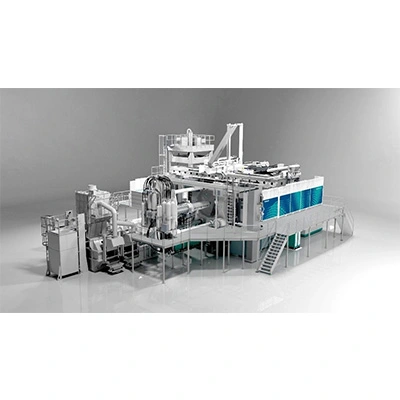

LK 1600T Horizontal Cold Chamber Die Casting Machine

The mass of the part is 11.4kg, and the material is ADC12 aluminum alloy. Casting projection area is 178200m㎡, average wall thickness is 3.7mm, belong to the complex structure of large thin-walled die casting. The die-casting machine used for the production test is LK 1600T horizontal cold chamber die-casting machine. The clutch housing is a pressure-resistant seal, which has high requirements for strength, wear resistance and gas tightness, etc. It is usually required to have less than 5cm3/min leakage under a pressure of 0.2MPa.