As the popularity of electric vehicles (EVs) continues to grow, manufacturers are seeking new and innovative ways to produce car parts that are durable, lightweight, and cost-effective. One solution that has gained significant attention in recent years is die cast aluminum alloys. In this article, we will discuss the advantages of die cast aluminum alloys for EV car parts.

Lightweight and Durable

One of the primary advantages of die cast aluminum alloys for EV car parts is that it is lightweight yet durable. EVs require parts that are lightweight to increase their efficiency and range. However, they also require parts that are strong enough to withstand the stresses of daily use. Aluminum alloys are an excellent choice for EV car parts because they are lightweight yet strong, making them an ideal material for many applications.

Cost-Effective

Another advantage of die cast aluminum alloys for EV car parts is that it is cost-effective. Aluminum alloys are readily available and easy to produce, making them an affordable option for many manufacturers. Additionally, the die casting process is efficient and can produce parts quickly, further reducing costs.

Excellent Thermal Conductivity

EVs generate a significant amount of heat, particularly in their batteries and power electronics. This heat must be dissipated to ensure that the components do not overheat and fail. Die cast aluminum alloys have excellent thermal conductivity, making it an ideal material for components that require heat dissipation.

Precision and Consistency

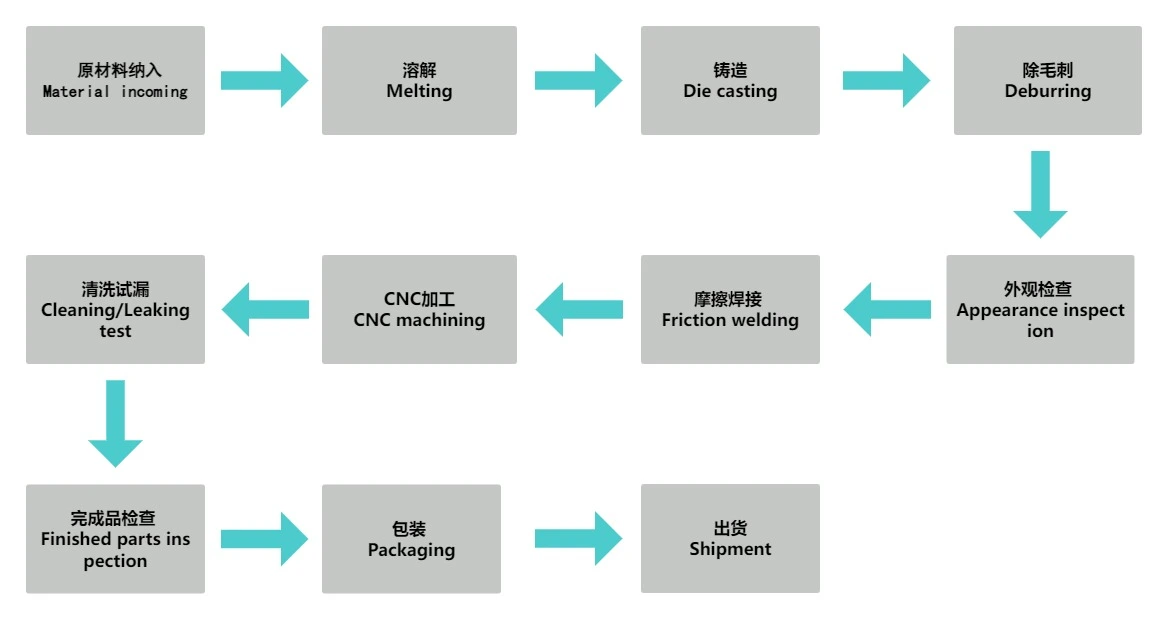

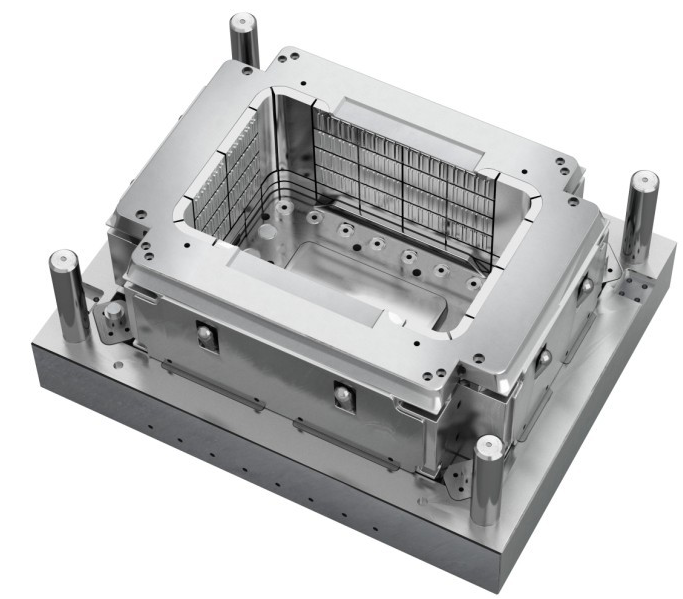

Die cast aluminum alloys also offer excellent precision and consistency in part production. The die casting process involves injecting molten metal into a mold at high pressure, resulting in a precisely shaped part that is identical to others produced by the same mold. This precision and consistency make die cast aluminum alloys an ideal choice for EV car parts that require tight tolerances.

Reduced Environmental Impact

Aluminum is a highly recyclable material, and die cast aluminum alloys for EV car parts can help reduce the environmental impact of the automotive industry. Using recycled aluminum can significantly reduce energy consumption and greenhouse gas emissions during the manufacturing process.

If you are looking for a reliable and high-quality manufacturer of die cast aluminum alloys EV car parts, EMP Tech Co.,Ltd is an excellent choice. With over ten years of experience in the industry, EMP Tech Co.,Ltd has established a reputation as a leading manufacturer of aluminum die casting parts.

EMP Tech Co.,Ltd has a state-of-the-art facility and uses advanced equipment to produce aluminum parts with precision and consistency. The company also has a robust quality control system in place, including regular inspections, testing, and certifications, to ensure consistent quality.

EMP Tech Co.,Ltd is committed to using sustainable manufacturing practices, including the use of recycled aluminum and reducing energy consumption during the manufacturing process. By choosing EMP Tech Co.,Ltd for your die cast aluminum alloys EV car parts, you can be confident that you are making a choice that is both cost-effective and environmentally friendly.

In conclusion, die cast aluminum alloys is an excellent choice for EV car parts due to its lightweight, durability, cost-effectiveness, excellent thermal conductivity, precision, and consistency. If you are looking for a reliable and high-quality manufacturer of die cast aluminum alloys EV car parts, consider EMP Tech Co.,Ltd. With their advanced facilities, commitment to sustainability, and excellent quality control measures, EMP Tech Co.,Ltd is an excellent choice for all your die cast aluminum alloys EV car part needs.