Die casting aluminum is a popular manufacturing process that is used to produce a wide range of products, from automotive parts to household appliances. One common question that people ask is whether die casting aluminum is stronger than regular aluminum. In this article, we will explore the differences between die casting aluminum and regular aluminum and determine which one is stronger.

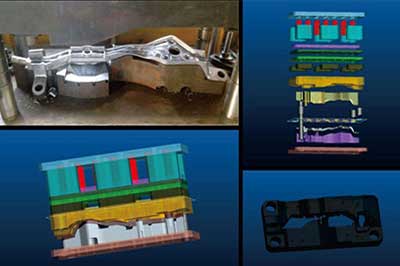

Die casting is a manufacturing process that is used to produce metal parts with high accuracy and consistency. In the die casting process, molten metal is injected under high pressure into a mold, where it solidifies into the desired shape. The mold is then opened, and the part is ejected. Die casting aluminum parts are known for their strength, durability, and high precision.

Regular aluminum is a metal that is widely used in a variety of applications due to its excellent strength-to-weight ratio, high thermal conductivity, and resistance to corrosion. Regular aluminum can be produced using several different manufacturing processes, including casting, forging, and extrusion.

When it comes to strength, both die casting aluminum and regular aluminum have their advantages and disadvantages. The strength of a material depends on several factors, including the specific alloy used, the manufacturing process, and the design of the part.

Strength of Die Casting Aluminum

Die casting aluminum parts are known for their high strength-to-weight ratio, which makes them an ideal choice for a wide range of applications. The die casting process can produce parts with complex shapes and tight tolerances, which can further enhance their strength. Additionally, die casting aluminum parts are typically heat-treated to further increase their strength and durability.

Strength of Regular Aluminum

Regular aluminum is also known for its strength, although it may not be as strong as die casting aluminum. The strength of regular aluminum depends on the specific alloy used, the manufacturing process, and the design of the part. Regular aluminum can be heat-treated to enhance its strength, but it may not be as strong as die casting aluminum due to its lower density.

Ultimately, the strength of a material depends on several factors, and it is difficult to say which one is stronger without considering the specific application. In some cases, die casting aluminum may be stronger than regular aluminum due to its higher density and the ability to produce complex shapes with tight tolerances. In other cases, regular aluminum may be stronger due to the specific alloy used, the manufacturing process, and the design of the part.

In conclusion, both die casting aluminum and regular aluminum are strong materials with their own advantages and disadvantages. The choice of which material to use depends on several factors, including the specific application, the design of the part, and the manufacturing process. When it comes to producing high-quality die casting aluminum parts, it is important to work with a manufacturer that has the experience and expertise to produce parts that meet the highest standards of quality and durability.