In the ever-evolving landscape of electric vehicle (EV) manufacturing, EMP Casting stands out as a leading provider of custom aluminum die casting solutions. Located in Zhaoqing, Guangdong, China, EMP Casting has carved a niche for itself by delivering high-quality, lightweight, and durable components tailored to the specific needs of the automotive industry, with a strong focus on EV applications.

Expertise in Custom Aluminum Die Casting

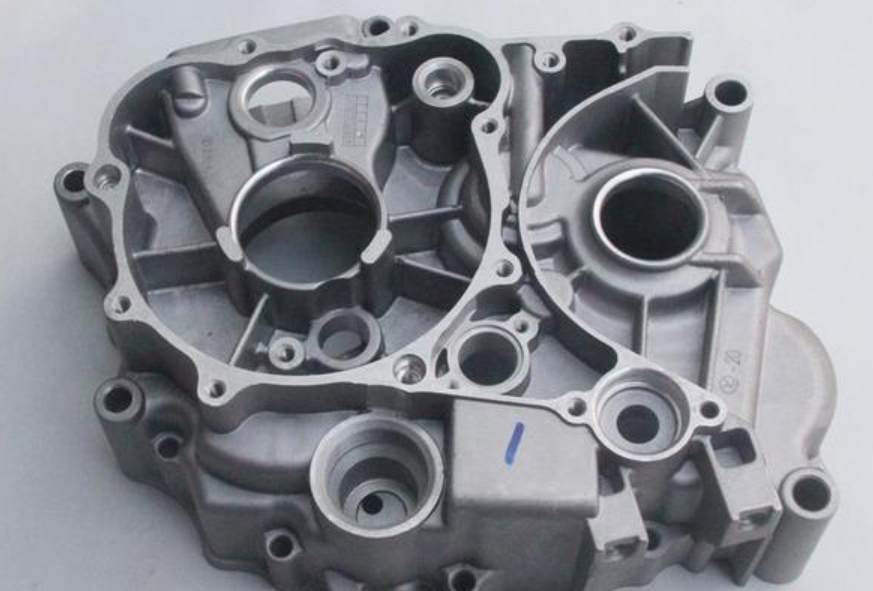

EMP Casting specializes in crafting custom aluminum die cast parts for electric cars, covering the entire manufacturing process from tooling design and testing to die casting, CNC machining, and finishing. This comprehensive approach ensures that clients receive a seamless experience, with every aspect of their project managed by a team of seasoned professionals.

Precision Engineering for EV Components

Electric cars demand components that are not only lightweight and durable but also capable of withstanding the demands of high-performance driving. EMP Casting excels in this regard, leveraging its advanced die casting techniques to produce EV battery enclosures, motor controllers, and other critical components with unmatched precision. The company's commitment to quality is evident in its rigorous quality control processes, which ensure that every casting meets the highest standards of dimensional accuracy and performance.

Advanced Facilities and Technology

EMP Casting boasts over 60 sets of advanced automatic production facilities and 150+ CNC machines, enabling it to handle even the most complex manufacturing requirements. This investment in technology allows the company to offer rapid molding and sampling times, often less than 50 days, ensuring that clients can keep pace with the fast-paced development cycles of the EV industry. Additionally, EMP Casting's factory is IATF 16949 (VDA6.3) certified, underscoring its commitment to continuous improvement and customer satisfaction.

Proactive Customer Service

EMP Casting prides itself on its proactive sales team, which is known for its excellent communication skills and willingness to work through client problems.. The company offers 24/7 service, ensuring inquiries and questions are handled promptly, often within 12 hours. This level of customer support fosters strong relationships with clients, many of whom are top brands in their respective industries, including Daimler, Continental, and Scania.

Addressing Common Manufacturing Challenges

EMP Casting is also committed to sharing its expertise and addressing common manufacturing challenges. For instance, the company has published knowledge center articles on how to prevent deformation of aluminum alloy die castings during production, providing valuable insights to clients and the broader industry.

Looking Ahead

As the EV industry continues to grow and evolve, EMP Casting remains committed to driving innovation and excellence in electric car parts manufacturing. With its focus on precision engineering, advanced technology, and unwavering commitment to quality, EMP Casting is poised to continue delivering high-quality components that meet the evolving needs of the automotive industry.

Whether you're looking for custom die casting solutions for your EV components or seeking a reliable partner for your manufacturing needs, EMP Casting is the name you can trust.