Introduction to Electric Vehicle Parts Manufacturing

The electric vehicle (EV) industry is experiencing unprecedented growth, driven by the global push towards sustainable transportation and the reduction of carbon emissions. As the demand for electric vehicles surges, the need for high-quality components becomes increasingly critical. The performance, safety, and efficiency of EVs heavily depend on the quality of their parts, making the role of manufacturers pivotal in the automotive supply chain.

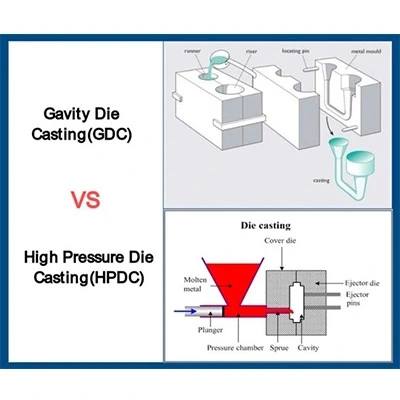

Role of Die Casting in EV Parts Manufacturing

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This technique is particularly advantageous for producing complex shapes with high precision and excellent surface finish. In the context of electric vehicles, die casting offers several benefits:

Precision and Complexity: Die casting allows for the creation of intricate designs that are essential for components like motor housings and battery cases.

Material Efficiency: The process minimizes waste, making it cost-effective and environmentally friendly.

Strength and Durability: Die-cast parts are known for their strength and resistance to wear and tear, which is crucial for the longevity of EV components.

Key Die Cast Parts in Electric Vehicles

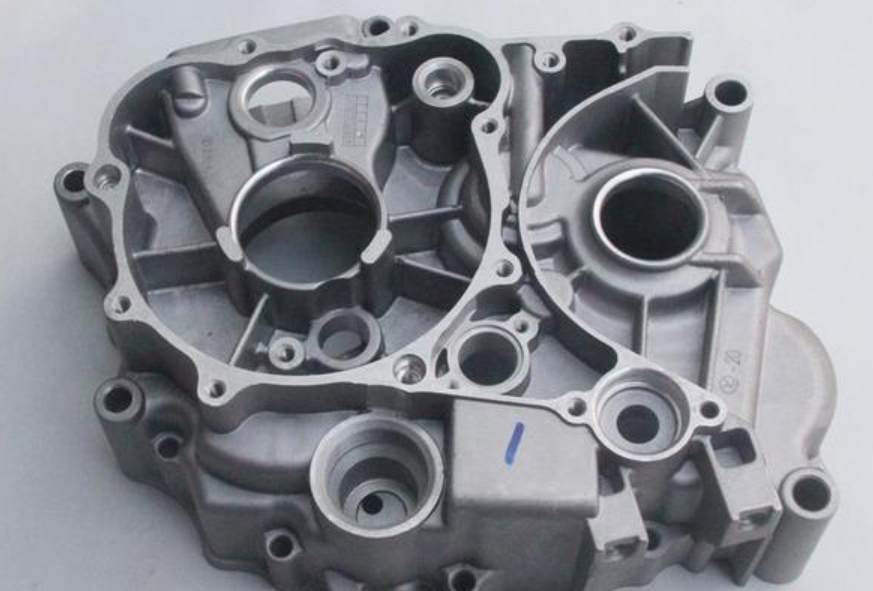

Motor Housing

One of the most critical die-cast components in electric vehicles is the motor housing. This part protects the electric motor from external elements and ensures its optimal performance. The precision and durability of die-cast motor housings are vital for maintaining the efficiency and reliability of the vehicle's propulsion system.

Battery Case

The battery case, also known as the battery box, is another essential component in electric vehicles. It houses the battery pack, providing protection against physical damage and environmental factors. Die casting is ideal for battery cases due to its ability to produce lightweight yet robust structures, which are crucial for enhancing the vehicle's range and performance.

Other Critical Components

In addition to motor housings and battery cases, die casting is used to manufacture various other EV components, such as electronic control units, motor control units, and structural parts. These components require the precision and strength that die casting provides, ensuring the overall reliability and efficiency of the vehicle.

EMP Die Casting: A Leader in Custom Auto Die Cast Parts

Introduction to EMP Die Casting

EMP Die Casting is a renowned name in the field of custom auto die cast parts, specializing in the production of high-quality components for electric vehicles. With a commitment to innovation and excellence, EMP Die Casting has established itself as a leader in the industry.

Specialization in Custom Die Cast Parts

EMP Die Casting's expertise lies in creating custom solutions tailored to the specific needs of their clients. Whether it's a unique motor housing design or a specialized battery case, EMP Die Casting has the capability to deliver precision-engineered parts that meet the highest standards of quality and performance.

Future Trends in Die Casting for Electric Vehicles

Innovations in Materials and Processes

The future of die casting in electric vehicles is marked by innovations in materials and processes. The development of new alloys and advanced casting techniques promises to enhance the strength, weight, and thermal properties of EV components, contributing to better performance and efficiency.

Impact on EV Performance and Efficiency

As die casting technology evolves, its impact on electric vehicle performance and efficiency will become even more significant. Lighter and stronger components will lead to improved energy efficiency, longer range, and enhanced safety, driving the adoption of electric vehicles worldwide.

Conclusion

In conclusion, die casting plays a crucial role in the manufacturing of electric vehicle parts, offering precision, strength, and efficiency. EMP Die Casting stands out as a leader in this field, providing high-quality, custom solutions that meet the evolving needs of the automotive industry. As the demand for electric vehicles continues to rise, the importance of reliable and innovative die-cast components will only grow, with EMP Die Casting at the forefront of this exciting transformation.

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China