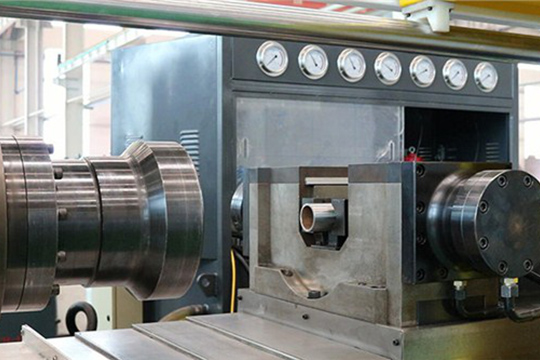

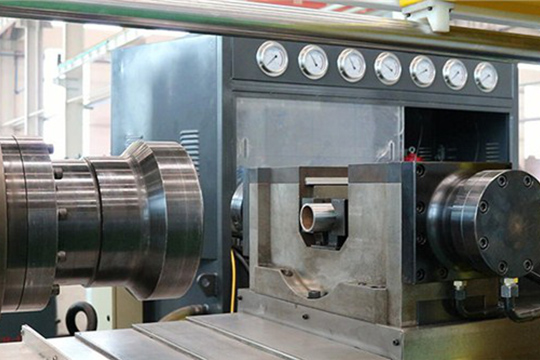

Friction welding is one of the welding methods of hot compression welding. The welding efficiency can reach 30~70%. Generally, friction welding with a large dynamic friction coefficient has higher efficiency. Its specific process is as follows:

1) The contact surface of the two weldments starts to rub. Firstly, the oxides and impurities attached to the surface are destroyed and eliminated. At the same time, the unevenness of the contact surface produces plastic deformation and the crystal grains are destroyed. As a result, the contact surface is heated and reveals a relatively flat and pure metal surface.

2) Continue to perform frictional motion on the contact surface of pure metal, so that the temperature of the contact surface continues to rise, the plastic deformation increases, and the phenomenon of metal mutual "bonding" (ie, local welding) begins to occur. As the frictional movement continues, the temperature near the contact surface of the weldment rises rapidly and approaches or reaches the welding temperature.

3) When the welding temperature is reached, the metal has great plasticity. When the relative movement is stopped rapidly and great upsetting pressure is applied, the two weldments will produce great plastic deformation, the metal atoms on the contact surface will be closer, mutual diffusion and intergranular connection will occur, and common recrystallization and intermediate compound will be formed. And a small amount of recrystallized grains to weld the two weldments together.

EMP Tech Co., Ltd is a professional manufacturer of precision aluminum die-casting products. We will use friction welding as a welding method in the manufacturing process to maximize the performance of aluminum die-casting products. Welcome to buy our products!