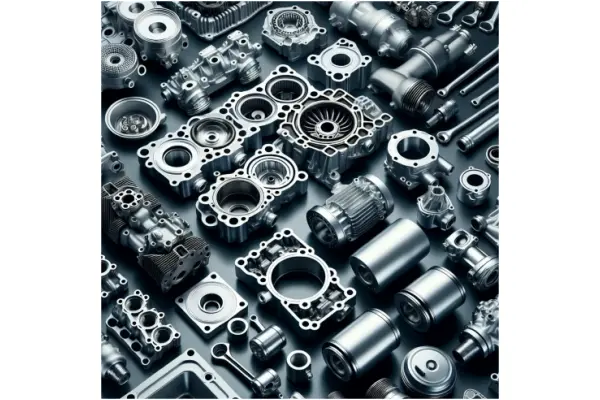

Excellent die casting molds contribute to high-quality products of die casting parts. In the process of die casting production, die casting mold is one of the important tools for the efficient production of die casting components. To complete the production of high-quality die casting parts, in addition to advanced die casting skills, equipment, and professional die casting talents, it is necessary to have a set of high-end die-casting molds. However, high-end die casting molds must have the following seven elements:

1. Qualified appearance and dimension of the die casting mold

The surface of the die casting mold has no defects, no weld marks, and the surface unevenness is less than 0.3mm. There are no air steaks, splay marks, and bubbles. The size and accuracy should meet the requirements of formal and effective mold opening drawings (or 3D files), and the surface misalignment should be less than 0.1mm.

2. Clear appearance of the die casting mold

The content of the nameplate of the die casting mold is intact, the characters are clear, and the placement is orderly. The surface of the die casting mold should not have pits, rusts, remaining rings, water vapor in and out, oil holes, etc., and other defects that affect the appearance.

3. Material and hardness of die casting mold

Anti-corrosion measures should take on the forming surface. The hardness of the molded parts of the die casting mold should not be lower than 50HRC, or the hardness of the surface hardening treatment should be higher than 600HV.

4. Cooling system of the die casting mold

The cooling or heating system of die casting mold should dredge. Water and oil flow channel spacers should be made of materials that are resistant to corrosion.

5. Feed system of the die casting mold

The gate of the die casting mold should not affect the appearance of the product and meet the product installation requirement. The cross-section and length of the runner should plan reasonably, and the process should shorten as much as possible under the premise of ensuring the molding quality, the cross-sectional area should reduce to shorten the filling and cooling time.

6. Parting line of the die casting mold

There should be no unevenness, pits, rusts, and other defects that affect the appearance of the front and back mold surfaces. The insert blocks combine with the mold frame, and there should be an open space less than 1mm around the round corners.

7. Storage and maintenance of die casting mold

Die casting mold cavity should be cleaned and sprayed with anti-rust oil. The water, liquid, gas, and electricity inlets and outlets of the die casting mold should seal to prevent foreign matter from entering. The product drawing, structure drawing, cooling, and heating system diagram, hot runner diagram, detailed information of parts and material suppliers, specification, test mode descriptions, delivery inspection certificates, and electronic files of the die casting mold must be complete.

When designing and manufacturing die-casting molds, the above seven elements must be possessed to ensure that the production process of die-casting molds is efficient, high-quality, and fast!