AUTO CAD is a generally used two-dimensional design software. MASTERCAM, SOLIDWORKS, UNI, and GRAPHICS are generally used three-dimensional software. If we use parts designed by two-dimensional software, three-dimensional software must be shifted first.

1. Process analysis of components die casting

Components designed by three-dimensional software can give a stereo display in any direction and any section. For easy observation and analysis, we should establish a complete three-dimensional concept, reduce the labour intensity of engineers on opening day, carry out process analysis of die-cast tooling thoroughly, and have a little error rate.

In the early stage of tooling design, from the perspective of die-casting process, adjustments and corrections to the structure and dimensions of the components are recommended. Obtain product design approval for parting plane location, gate size, gate location.

2. Casting design

According to the die-casting process plan, determine the parting surface, corresponding to the drafting direction, processing, core-pulling parts, and plans. Control the key dimensions of the big end and other parts, determine the machining allowance, and complete the die-casting tooling design.

After product design approval, the casting model will be used for a die casting die design. We just need to take contraction into account. Change parts drawing into casting drawing, and calculate the size of core-forming.

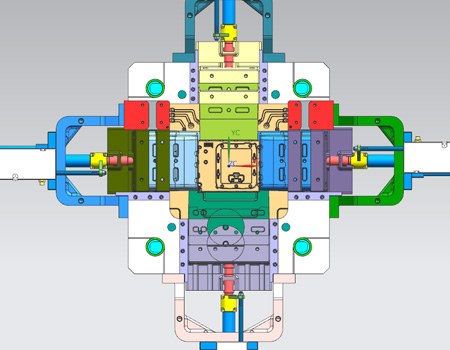

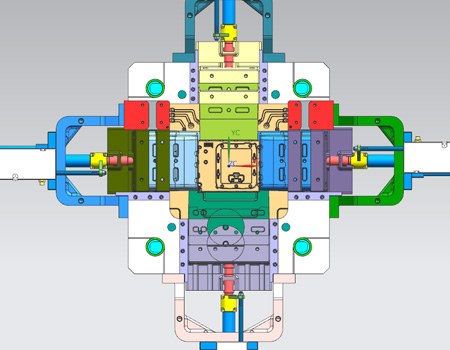

3. Overall design of die-cast tooling

According to the casting data, weight, wall thickness, structural features, projected area, etc., start the die-casting mold design. Preliminarily determine process parameters, model selection and tooling dimensions, installation locations, ejection, mold opening, and assembly. Check for interference and verify the model and process parameter settings again.

Inquire parting surface, the projected area of the core-pulling face, and verify clamping force and core locking force.

1. Good tooling material.

2. Processing and heat treatment of die-cast tooling.

3. Control of casting production process

Improving further the economic benefit of tooling needs a normative treatment process to get the best performance. During the production process of die-cast tooling, it should accord with the normative heat treatment process to get the best performance.

During the production process of die casting, it should accord with normative usage, maintenance, and safeguard to prolong the tooling lifetime.

Established in 2004, EMP Tech Co., Ltd. owns a manufacturing plant of 50,000 square meters as well as 500 experienced engineers and support staff.

EMP Tech Co., Ltd. mainly serves automobile, machinery, industry, telecommunication, and electronics industries. The continuous research and development in customized aluminum die casting area earns us more than 17 patents. Our increasing client bases are spread all over 25 countries and regions. We are waiting for all customers to consult us.