1. Description

In the die casting process, the factors of pressure and insufficient clamping force, etc. It is inevitable that die casting parts will have burrs. Recently, with the increasing quality requirements of die castings, the requirements for burrs have become more strict, and methods for deburring have emerged endlessly.

2. Method

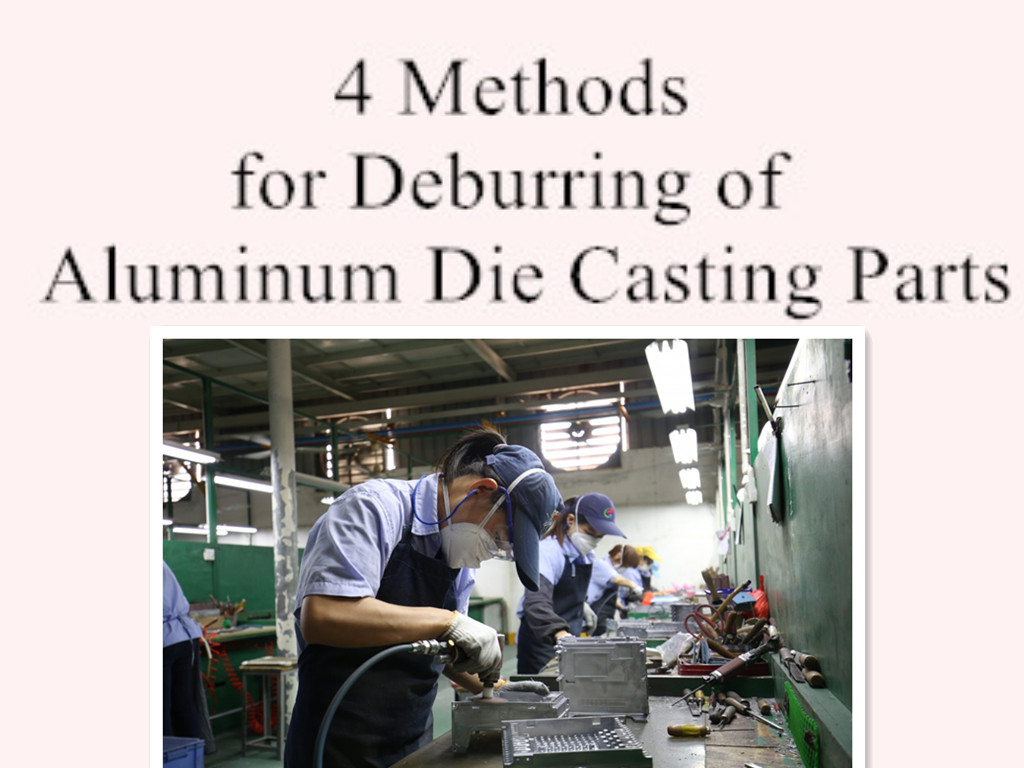

1) Manual Deburring

This is the most traditional and commonly used method in die casting plants, using files (files include manual files and pneumatic files), sandpaper, belt machines, grinding heads, etc. as auxiliary tools.

Application: Low technical experience for workers, suitable for aluminum alloy die castings with small burrs and simple product structure.

2) Grinding and Deburring (Vibration Grinding)

This type of deburring includes vibration, sandblasting, rollers, etc., which are currently used in many die casting plants.

Application: suitable for small aluminum alloy die castings with larger quantities in mass production.

3) Trimming

Use a production die to cooperate with a punch for deburring.

Application: Suitable for aluminum alloy die castings with simple parting surfaces, and the efficiency and deburring effect are better than manual.

4) Automatic Deburring

The principle is similar to manual deburring, except that the power is turned into a robot. With the support of programming technology and force control technology, flexible grinding (pressure and speed conversion) is realized, and the advantages of robot deburring are prominent.

Most of our die-casting parts use automatic deburring, which not only saves labour costs but also improves production efficiency.