The AAPEX Show takes place from November 5th to November 8th, 2019 at the Las Vegas Convention Center located at 3150 Paradise Road, Las Vegas, NV 89109. As an IATF certified aluminum die casting parts manufacturer in the aluminum foundry industry, EMP participated in the exhibition and gained a chance to know more customers in various industries and establish cooperation.

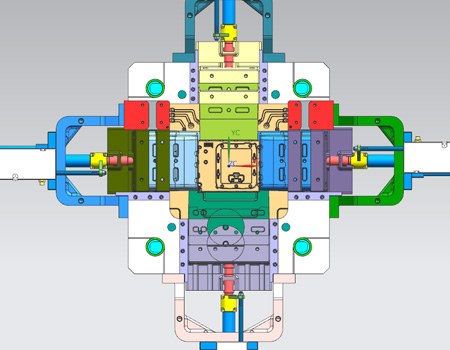

We presented in the exhibition the cast aluminum products like automotive wiper windshield parts, motor housing, PDU housing, motor controller, transmission parts, which caught lots of attention from the customer, especially those who search for the electric vehicle components.

During the AAPEX show, lots of professionals in the automotive industry got to know about EMP on our booth and lots of partners we’ve been cooperating with for years also come to visit and support us, it was a great and fruitful experience exhibiting in the AAPEX exhibition.