With the development of society and the progress of the times, the die-casting industry, as a pillar of the new industry, has achieved amazing results. In recent years, aluminum alloy die-casting technology has been widely used in the field of automobile manufacturing, and both mechanical equipment and die-casting technology have undergone great changes.

1. The current status of aluminum alloy die-casting industry

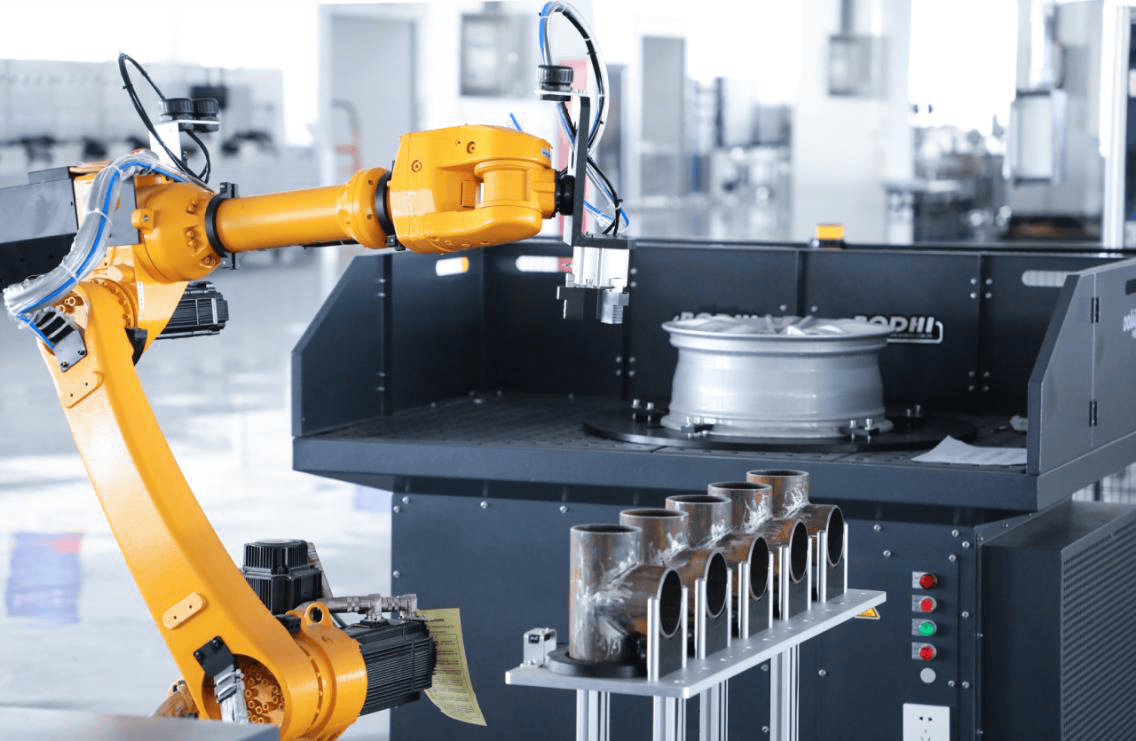

As the most important industry in the die-casting industry, the auto parts manufacturing industry, especially the increase in demand for automotive aluminum alloy die-casting products, has a direct impact on the development of the entire die-casting industry. From the perspective of the structure of the car, the application of aluminum alloy die-casting parts in addition to some precision parts, such as the engine, gearbox, and electronic control system, the car body frame also began to use aluminum alloy die-casting technology.

To meet the market demand, the die-casting process is improved from the following aspects:

With the goal of green and pollution-free, research and development of green aluminum alloy materials:

Transform the die-casting process;

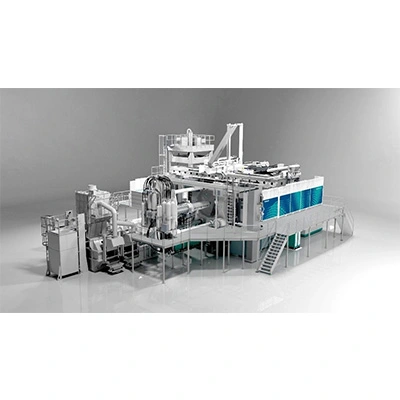

Improve the demand capability of the die-casting industry;

Improve the technology of die-casting aluminum alloy auto parts.

2. Development of Aluminum Alloy Die Casting industry

Judging from the current development of aluminum alloy die-casting technology, the aluminum alloy die-casting industry will continue to maintain a relatively high growth rate under the stimulation of the huge market demand. The development of the aluminum alloy die-casting industry has huge development potential and room for expansion. The rapid growth of the alloy die casting industry brings opportunities. Aluminum alloy die-casting aluminum alloy cylinder blocks for automobile engines has developed rapidly, and auto parts die-casting has formed a huge market. The lightweight aluminum alloy dies castings have become an important development trend. Taking automobiles as an example, the goal of a new generation of automobiles is to reduce the fuel consumption to 3L per 100km, which requires a 40% to 50% reduction in vehicle mass. The urgent need for lightweight automobiles provides broad prospects for the development of the aluminum alloy die-casting industry. The strong domestic and external demand of the automobile industry has promoted the rapid development of the parts manufacturing industry, of which aluminum alloy die castings account for a large share.