From the perspective of the whole automobile structure, in addition to the automobile engine, gearbox, transmission system, steering system, electronic control system using a large number of precision die casting parts, body frame and other large components also began to use aluminum alloy die casting parts. With the increasing attention to energy saving and environmental protection of automobiles, there is the trend of replacing steel and iron with aluminum in the automobile industry in the past 30 years, and the global market of automobile aluminum alloy die casting part has been growing rapidly. According to the North American Die Casting Association (NADCA), global sales of aluminum alloy die casting part for automotive applications will reach 16.3520 million tons in 2025, up 83.19% from 2012.

The benefits brought by the increase of automobile aluminum consumption are mainly reflected in the following aspects:

(1) Promote automobile lightweight, energy saving and consumption reduction, which is conducive to environmental protection

A 10% reduction in the weight of a 1300kg car would reduce fuel consumption by 8%, or 0.7kg of petrol per 100km travelled.

(2) Aluminum alloy die casting part can be recycled to further save energy

Generally, the recovery rate of aluminum alloy is not less than 85%. 60% of aluminum alloy used in automobiles comes from recycled waste materials. By 2010, this number has risen to about 95%.

(3) Increase corrosion resistance and prolong service life

Aluminum and aluminum alloy die casting part can form a layer of dense oxide film on the surface under normal temperature and natural conditions, so its corrosion resistance and oxidation resistance is much higher than that of iron and steel materials. At the same time, aluminum alloy has excellent surface treatment performance, suitable for oxidation coloring, powder, paint and other surface treatment technologies.

(4) Help to improve the balance and safety of car driving

The use of aluminum alloy wheels reduces the vibration, allowing for the use of lighter rebound buffers; In addition, because the use of aluminum alloy material is to reduce the weight of the car without reducing the volume of the car, so that the car is more stable. Under impact, the aluminum alloy die casting part can absorb and disperse more energy, thus making it safer and more comfortable.

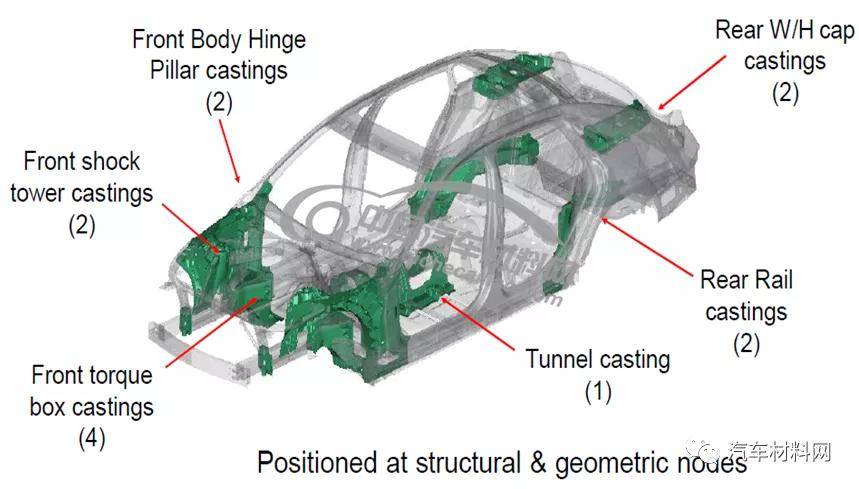

Die cast aluminum alloy has the characteristics of large freedom of design, easy to form, etc. The application parts of the body system are mainly distributed in the shock tower, longitudinal beam, joint, middle passage, front vertical plate and other parts. The Cadillac CT6, which combines 227 steel parts into 31 cast aluminum parts, is also a typical model.

In the aspect of aluminum alloy shock absorber, Al-Si-Mg and Al-Mg series aluminum alloy are mainly used, among which SF36 (AlSi10MnMg) is the most mature.

With the continuous development of auto industry, vehicle manufacturers and suppliers have higher requirements on reliability, accuracy, technical content, energy conservation, environmental protection and so on of auto parts. When choosing the upstream suppliers, technical strength, product quality, manufacturing capability, availability and the cost control are the important factors. EMP is one of the leading aluminum die casting manufacturers in Guangdong Province. Founded in 2004, EMP produces aluminum die casting products through professional mold design and new product development.