In the dynamic world of automotive manufacturing, selecting the right auto parts manufacturer is a critical decision that impacts the quality, performance, and longevity of vehicles. With advancements in technology and the shift towards electric vehicles (EVs), companies like EMP Casting are at the forefront, specializing in die-casting essential components such as motor housings and EV battery cases. This article delves into the key considerations for choosing a reliable manufacturer, emphasizing the benefits of die casting in auto parts production.

Why Choose an Auto Parts Manufacturer Specializing in Die Casting?

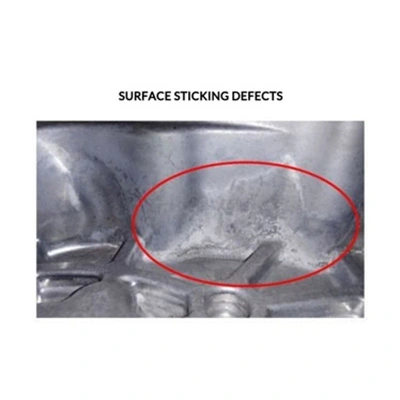

Precision and Quality: The die-casting process is renowned for its ability to produce components with high precision and excellent surface finish. For critical parts like motor housings and EV battery cases, this precision ensures a snug fit and optimal performance, reducing the risk of mechanical failure and improving vehicle reliability.

Durability and Strength: Die-cast parts are known for their superior strength and durability. This manufacturing technique creates components capable of withstanding high stress and extreme environmental conditions, making them ideal for automotive applications.

Cost-Effectiveness: Die casting is an efficient process that supports large-scale production while maintaining cost-effectiveness. This efficiency is crucial for auto manufacturers looking to optimize production costs without compromising on quality.

Sustainability and Environmental Responsibility: As the automotive industry moves towards greener practices, die casting offers an environmentally friendly solution. It minimizes waste and allows for the use of recyclable materials, aligning with the industry's sustainability goals.

Flexibility in Design: Die casting provides flexibility in design, allowing manufacturers to create complex shapes and intricate designs with minimal machining. This capability supports innovation and helps manufacturers meet the evolving demands of automotive design.

EMP Casting: A Leader in Auto Parts Manufacturing

At EMP Casting, we leverage our extensive experience and cutting-edge technology to produce high-quality auto parts that meet the demands of the modern automotive industry. Our expertise in die casting enables us to manufacture components like motor housings and EV battery cases with precision and efficiency. We are committed to innovation, quality, and customer satisfaction, making us a trusted partner in automotive manufacturing.

Tips for Choosing the Right Manufacturer

When selecting an auto parts manufacturer, consider these essential factors:

Experience and Expertise: Opt for manufacturers with a solid track record and specialized expertise in die casting. Experience often translates into better quality control and production efficiency.

Technology and Innovation: Ensure the manufacturer uses state-of-the-art technology to guarantee precision and quality in their products. Innovative processes can lead to better-performing and more reliable components.

Customer Service and Support: A reliable manufacturer should offer excellent customer service and be attentive to your needs, providing support throughout the production process.

Reputation and Reliability: Research reviews and testimonials to assess the manufacturer's reputation. A company with a strong reputation is likely to deliver consistent quality and reliability.

By focusing on these factors, you can choose a manufacturer that will provide high-quality, durable, and cost-effective auto parts, ensuring the success of your automotive projects.

For more information on how EMP Casting can meet your auto parts manufacturing needs, please contact us today.

With this comprehensive guide, you will be well-equipped to make informed decisions that will enhance the quality and reliability of your automotive products, all while partnering with trusted industry leaders like EMP Casting.

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China