In an era where fuel efficiency and sustainability are paramount, the automotive industry has been making significant strides towards greener and more economical transportation. One of the key players in this evolution is the utilization of aluminum automotive components. In this blog, we will delve into the world of aluminum in automobiles, focusing on its profound impact on fuel efficiency.

Lightweight Marvel: The first and most compelling factor is the lightweight nature of aluminum. Aluminum is significantly lighter than traditional materials like steel, which means that when used in key components of a vehicle, it can dramatically reduce the overall weight of the vehicle. A lighter car demands less energy to move, resulting in improved fuel efficiency. Whether it's the chassis, body panels, or engine components, aluminum's weight savings contribute to lower fuel consumption.

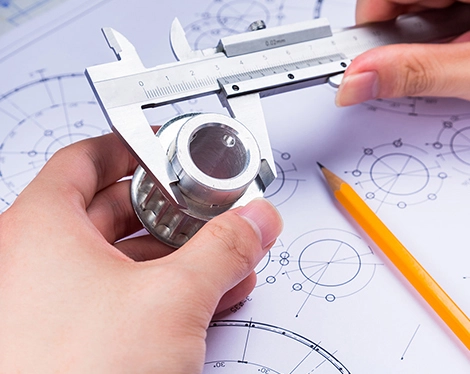

Optimized Engines: Aluminum's exceptional heat dissipation properties make it an ideal material for engine components. Engines equipped with aluminum parts, such as cylinder heads and blocks, can run at higher compression ratios, leading to enhanced thermal efficiency. This, in turn, translates to more power output for a given amount of fuel, ultimately reducing fuel consumption.

Aerodynamic Elegance: Many automakers are using aluminum to create sleek and aerodynamic body designs. Aluminum's malleability allows for intricate shaping and precision, resulting in vehicles with reduced air resistance. This sleek design, coupled with the weight savings, means that cars can cut through the air more efficiently, consuming less fuel in the process.

The use of aluminum automotive components has already led to significant improvements in fuel efficiency across a wide range of vehicle types. Manufacturers have embraced aluminum in various ways, from lightweight aluminum alloy wheels to entire aluminum-intensive vehicle platforms. Hybrid and electric vehicles benefit as well since a lighter chassis requires less power to propel.

Cost Considerations: While aluminum offers substantial benefits, it is more expensive to produce than traditional materials like steel. This cost can affect the overall price of a vehicle, making it a factor that manufacturers must balance with the potential fuel efficiency gains.

Recycling and Sustainability: Aluminum's environmental benefits are clear, but ensuring responsible recycling and sustainability in aluminum production are essential to realize its full potential. Fortunately, the aluminum industry is making strides in this regard.

Repairability: Repairing aluminum automotive components can be more challenging and costly than repairing steel, as specialized tools and skills are often required. This is a consideration for both vehicle owners and repair facilities.

Aluminum automotive components have indeed unveiled a new era of fuel efficiency in the automotive industry. The lightweight, durable, and thermally efficient nature of aluminum contributes to reduced fuel consumption and emissions, while also enhancing overall vehicle performance. As technology continues to advance and aluminum becomes more accessible, we can expect even more innovative uses of this remarkable material in future automotive designs. The road to a greener and more fuel-efficient future is paved with aluminum, and it's a journey that's worth celebrating.