In the automotive industry today, traditional New Energy / Electric Vehicle (NEV/EV) battery packs typically adopt steel-framed battery pack structures to meet various puncture-proof, explosion-proof, and load-bearing performance requirements borne by industry and governmental regulations.

While the steel frame delivers excellent performance for these required tasks, ultimately, one area where it hinders the performance of the NEV/EV is in overall vehicle efficiency. Because the steel-framed structure is very heavy it increases the weight of the vehicle, which directly affects its rolling resistance. Higher rolling resistance for the vehicle means higher energy requirements to get the vehicle up to speed, as well as maintaining steady-state cruising.

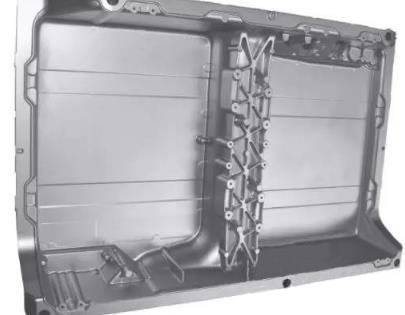

Because of this, researchers have been looking for ways to increase the overall efficiency of the NEV/EV by reducing the weight of the battery pack. One of the directions researchers have been exploring has been in the use of novel lightweight aluminum alloy battery pack enclosures formed with high-pressure die-casting.

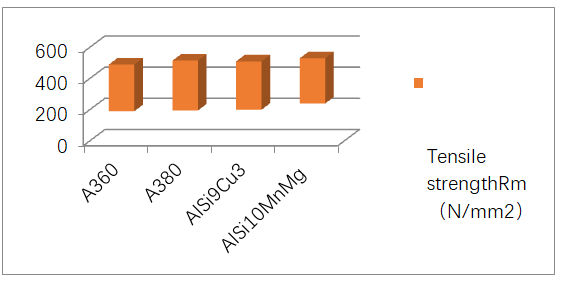

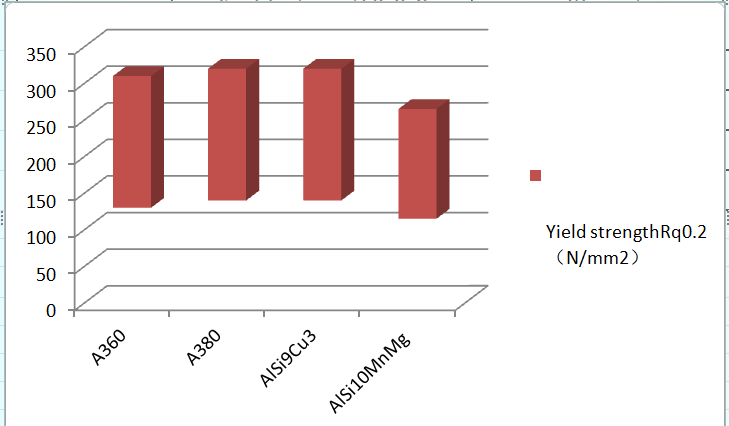

EN AC-43500, (or AlSi10MnMg for the EN chemical designation), is the main aluminum alloy currently used in the formation of structural parts and subassemblies that have high mechanical performance requirements in the automotive chassis. This alloy, mainly used in the oil pan, sunroof & convertible roof subassemblies, front axles, engine mounts, suspension mount assemblies, multi-component subframes, etc. The following table compares the physical properties of AlSi10MnMg and other aluminum alloy materials.

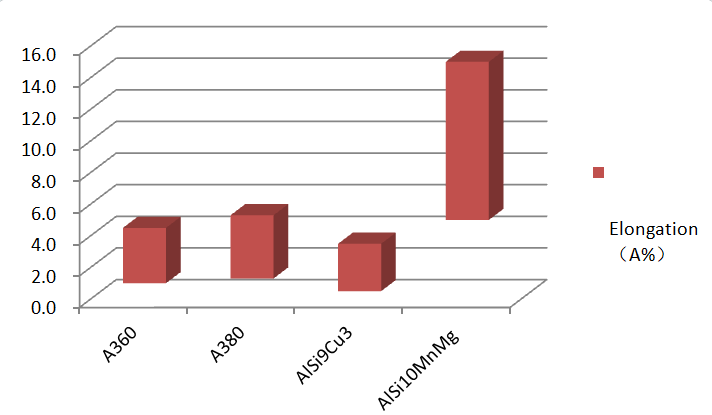

In the as-cast condition, the strain value of the standard die-cast alloy is 5-10%. In order to achieve the maximum strain value at moderate strength values, the EN AC-43500 AlSi10MnMg die-cast alloy was developed. With additional heat treatment, elongation of more than 15% can be obtained, or the yield limit of 260 Mpa can be reached.

In addition to these special mechanical properties, EN AC-43500 AlSi10MnMg alloy also has the following characteristics in die casting applications: excellent casting performance, no adhesion on die-casting molds, good corrosion resistance, high durability, good welding performance, suitable for punching and pressing.

With different heat treatment processes (see table below), the mechanical properties of the alloy can be adjusted.

| Condition | Tensile Strength | Yield Limit | Elongation |

| Rm(N/mm2) | Rq0.2(N/mm2) | (A%) | |

| F | 250-290 | 120-150 | 5月10日 |

| T4 | 210-260 | 95-140 | 15-22 |

| T5 | 275-340 | 155-245 | 4月9日 |

| T6 | 290-340 | 210-280 | 7月12日 |

| T7 | 200-240 | 120-170 | 15-20 |

EMP's engineering team, armed with years of aluminum alloy die-casting process experience, prepared experiments comparing the characteristics of various materials and landed on a technical solution combining EN AC-43500 AlSi10MnMg material with advanced die-casting technology.

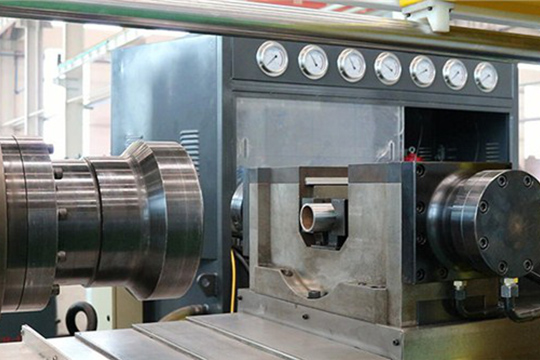

In order to make the castings meet the conditions of heat treatment, the engineers repeatedly tested different die casting methods and determined the vacuum die casting process due to its superior suitability to heat treatment. Castings produced under vacuum die-casting conditions have high compactness and fully meet the conditions of T4-T7 heat treatment.

After corresponding heat treatment, the elongation rate (A%) of EN AC-43500 AlSi10MnMg can reach 15-20, which is 30-60 times that of general aluminum alloy materials, which meets the requirements for high strength, durable, structural component suitable for lightweight battery pack enclosures for NEV/EV usage.