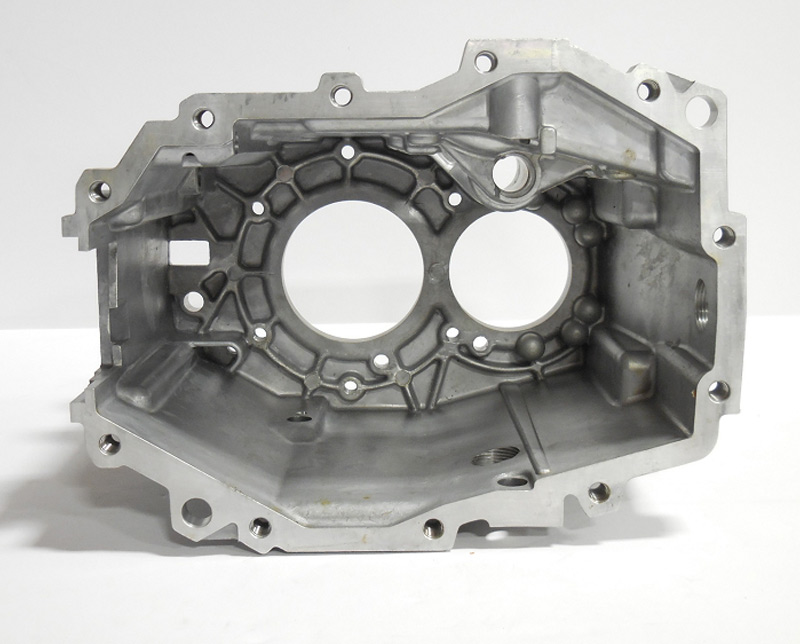

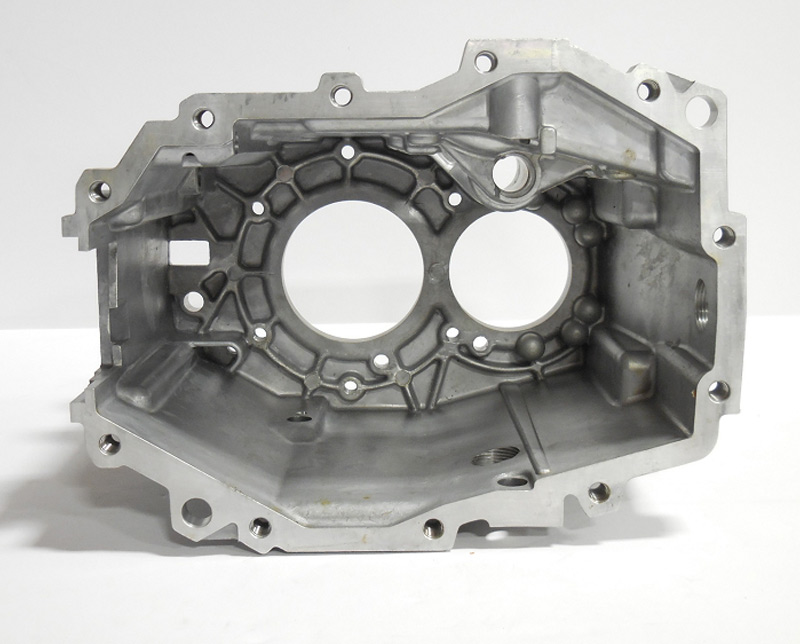

With the improvement of aluminum alloy casting technology, most of the aluminum castings are metal mold castings and shell mold precision castings. The workpiece surface obtained by the two kinds of castings is finer, and the internal structure is more exquisite. But sometimes the workpiece blackening phenomenon will appear in the process of use. How is this blackening phenomenon formed? Here are exclusive explanations of the reasons for aluminum casting blackening.

1. The influence of storage environment. If aluminum castings are stored in humid places for a long time, mold grows, which leads to blackening.

2. The machined foundry aluminum casting can not be cleaned thoroughly without cleaning treatment or simply with water, which leads to the residual cutting fluid, saponification fluid and other corrosive substances on the surface and speeds up the blackening.

3. The blackening phenomenon caused by the use of environment. Corrosive gas or chemicals in the working environment of aluminum castings will result in corrosion.

The above three points are the main reasons for the blackening of aluminum castings in the later stage. We hope users can pay attention to them.

EMP Tech Co.,Ltd. has experienced engineering, technical management and quality assurance teams, and we are ready to support the most challenging projects. We have provided our customers with precision machining prototypes, mold designs, extensive product testings and mass production assistance. If you are interested in cooperating with us, please feel free to contact us.