Many customers will ask my product-aluminum die casting parts can be anodized? At present, die casting parts can be anodized, but is difficult. Silicone is an important element that affects the whole anodic oxidation. The content of silicone should not be more that 12%, because silicone is an inert element, while anodic oxidation relies on the chemical reaction between acid and aluminum alloy to generate oxide film on the surface. Cast aluminum alloys and die castings generally contain a high silicon content. The anodized film is dark. It is impossible to obtain a colorless and transparent oxide film. As the silicon content increases, the color of the anodized film changes from light gray to Dark gray to dark gray. it will react chemically with the anodization potion, and the product will be gray-black after anodizing. However, this does not affect its anti-corrosion features. Therefore, cast aluminum alloy can be anodized but is not suitable.

Also, EMP could provide several suggestions to optimize this issue as below:

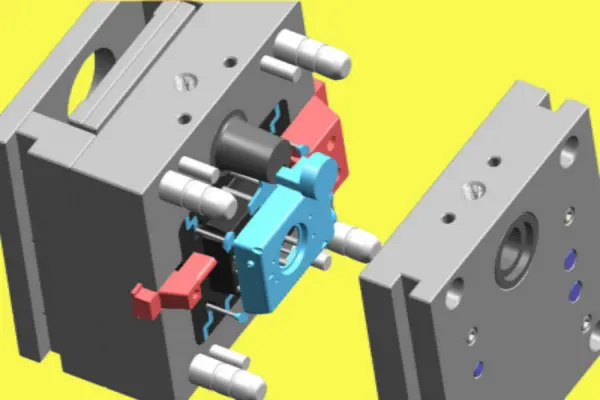

1. Mold runner, gate design, mold temperature control

2. Use of raw materials to avoid pollution

3. Process control of die casting process to reduce marks and black watermarks

4. Pre-processing of rough parts