Improve efficiency and output

1. The foam model used for the infiltration of aluminum alloy die castings is mechanically foamed. While ensuring the quality of the model, the production speed is also quite rapid.

2. The infiltration process of aluminum alloy die castings simplifies the cumbersome steps of the traditional process, such as molding the core, which is laborious and inefficient.

3. The aluminum alloy dies castings are impregnated into one box for multiple injections, and multiple boxes can be poured at the same time until the metal solution is used.

Cost-saving

1. The mold used for the infiltration of aluminum alloy die castings can be used for life with almost no loss, reducing or eliminating mold costs.

2. The impregnation of aluminum alloy die castings abandons the traditional molding process of core-setting, which saves labor and reduces manufacturing costs.

3. The infiltration of aluminum alloy die castings have gradually developed from the foundry industry with many male workers to many female workers. Also, labor is greatly reduced in all aspects, and the cost of workers' wages is reduced in disguise.

4. The sand used for infiltration of aluminum alloy die castings can be recycled, and the loss is 2%-5%.

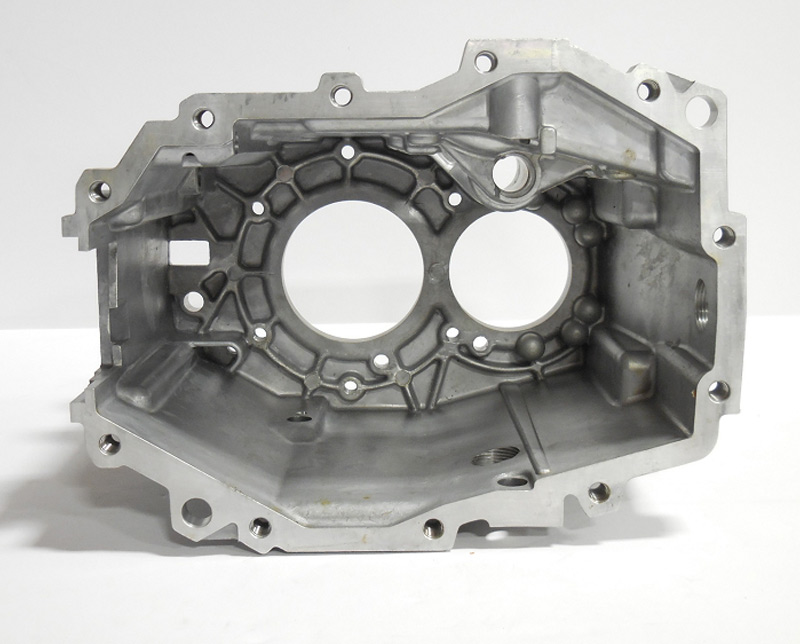

The impregnation treatment is to immerse the die-casting parts in an impregnating liquid with penetrating and filling functions, so that the impregnating liquid penetrates the loose parts inside the die-casting parts, thereby improving the air-tightness of the die-casting parts.