Automobile lightweight technology mainly includes lightweight material technology, lightweight design technology, and lightweight manufacturing technology. With the current domestic technology, it is difficult to breakthrough in a short time, the research and development cycle is long, and the cost is high. The development of new materials for automobiles can effectively reduce the total mass of automobiles, and is also the main development direction of automobile lightweight technology.

Lightweight automotive material-aluminum alloy.

Aluminum is the first lightweight material used in automobiles. Aluminum alloy has low density, good malleability, easy forming and processing, and good casting performance. In addition, the form also includes plates, profiles, pipes, and high-performance cast aluminum. At present, aluminum castings account for about 80% of all aluminum products. Pistons made of aluminum-based composite materials are 10% lighter than cast iron pistons. Light and medium-sized vehicles use aluminum alloy wheels, which are 30%-40% lighter than traditional steel wheels, such as AlSi10MgFe, ENAC43400, AlSi9Cu3, AlSi10MnMg, etc.

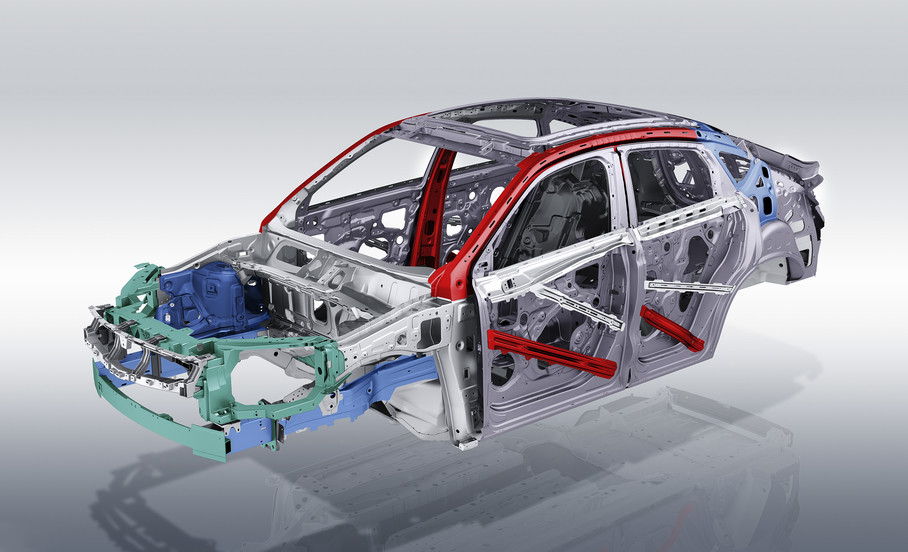

Lightweight automobile material-magnesium alloy.

Magnesium can reduce the weight of aluminum by 15% to 20%. Magnesium alloy is currently the lightest metal structural material, with high specific strength, high specific rigidity, impact resistance, and good casting performance. Magnesium alloys for automobiles started late, and magnesium for vehicles is growing at an average annual rate of 20%. At present, magnesium alloy mainly manufactures large-area structural parts such as chassis, body, steering wheel, seat frame, wheels, and some thin-walled parts.

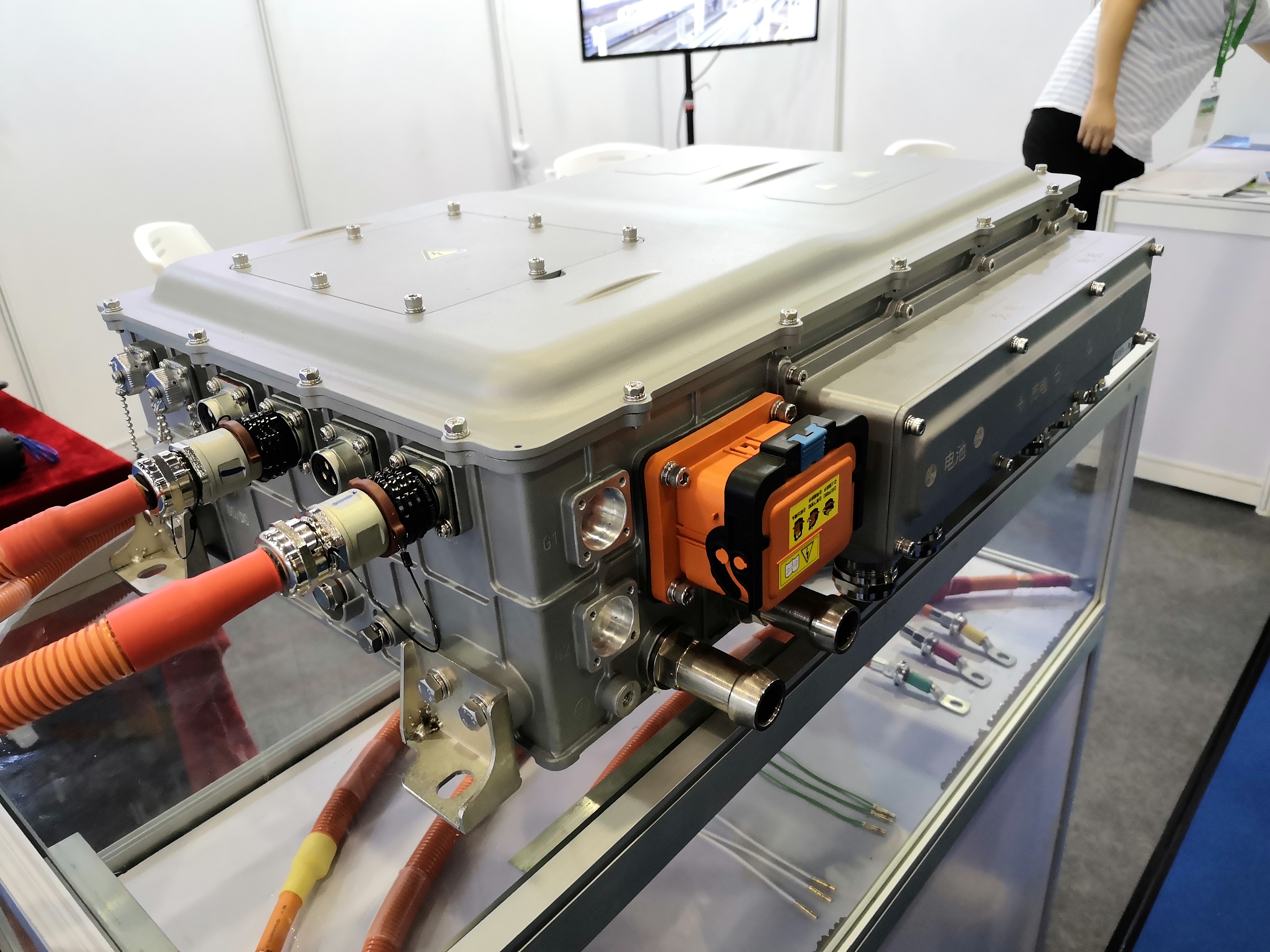

In the future, it is necessary to increase the coordination of the automotive lightweight industry chain and the connection of the technology chain, strengthen software development, and further increase the innovation of universities. Enterprises need to increase the use of power batteries and the recycling of automotive materials and other technological breakthroughs, pay attention to the high-performance lightweight of core components and power systems, and promote the rapid development of the automotive industry to high-performance transformation.