In recent years, the influx of capital has driven the investment expansion of electric vehicle industry chain projects. T new energy power battery industry represented by lithium-ion batteries has undergone a structural extension. Lithium batteries are the core component of new energy vehicles, accounting for 40% of the total production costs of new energy vehicles.

Electric compressor:

The new energy thermal management system has undergone earth-shaking changes, from traditional cabin cooling to cabin and battery cooling and heating. A wide range of cooling and heating capacity adjustments is an urgent issue for thermal management. The CO2 rotor electric compressor solves the problem of low-temperature heating.

It has the technical characteristics of high efficiency, low noise, and lightweight. And can meet the needs of high-efficiency refrigeration and low-temperature heating.

Even in a low-temperature environment of -35℃, the heating capacity is still strong. Users in cold regions no longer need to "cover a quilt" to drive. They solve the problem of rapid decay of endurance in cold conditions. Compared with traditional heat pumps, the cruising range is increased by 20%.

Main die casting drive motor:

As the "engine" of a new energy vehicle, the motor is responsible for converting electrical energy into the battery system. The second is kinetic energy. When you don't need to drive a car, you can also use the characteristics of a generator to convert the kinetic energy of the auto into electrical energy and store it back in the battery.

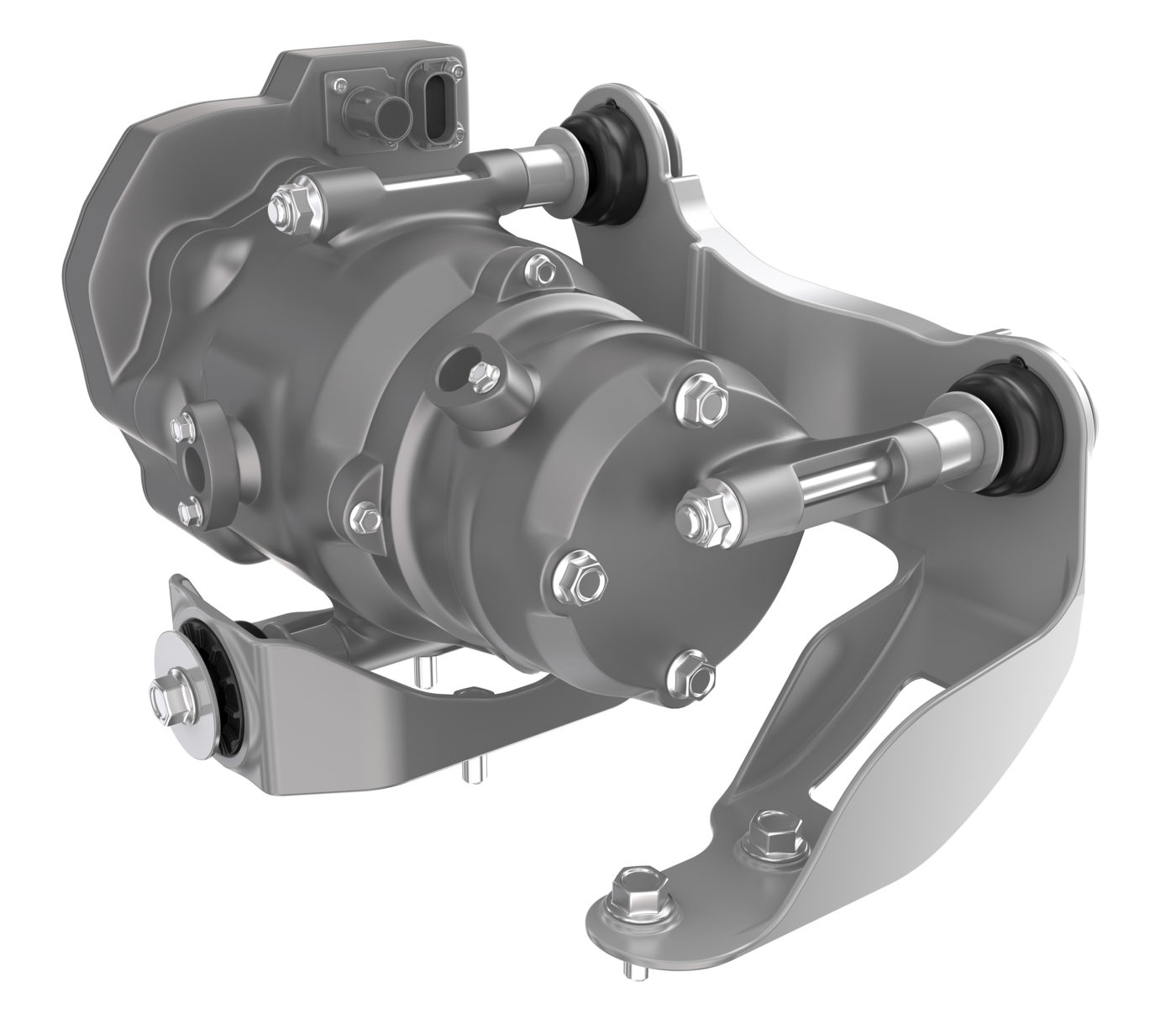

EPS motor:

EPS motors are electric power steering, mainly used in the automotive industry. The current EPS motor drive system is an important research direction in the field of automotive electrical technology and has good potential.

Electronic water pump:

A kind of piezoelectric material as the powerplant, complete the electronic control from control to drive. And with the Electronic integration system to control the new type of water pump for liquid transmission, to realize the adjustability and accuracy of Liquid transfer.

Electronic oil pump:

The function of the oil pump is to deliver the oil to the friction part of the engine so that the oil circulates in the lubrication circuit to ensure good lubrication of the engine. Oil pumps are mostly gear pumps, which consist of gear pump bodies.

When the engine is working, the camshaft drives the driving gear of the pump body to rotate. The gear oil flows along the inner wall of the pump from the oil inlet to the oil outlet, forming a low pressure, generating suction, and the oil in the oil tank is sucked into the oil inlet. The grease at the oil outlet accumulates more and more, the pressure increases, and the oil is pressed to the friction part to achieve forced lubrication.