1. Friction Stir Welding (Friction Stir Welding, FSW for short)--Using a special form of stirring head to move forward while rotating, the friction between the stirring head and the casting parts generates heat, and the heat of friction makes the metal in the part in a thermoplastic state, and under the pressure of the stirring head, the parts to be welded together to one part.

2. Advantages of friction stir welding:

Good Welding Quality: The weld is extruded in a thermoplastic state, and belongs to solid-phase welding, which has excellent mechanical properties.

Widely used: Not limited by shaft parts, it can be welded straight welds, fillet welds, girth welds, etc., expanding the scope of application

No need for high operating skills and training: Friction stir welding uses automated mechanical equipment for welding, avoiding the dependence on the technical proficiency of operators, stable quality, and high repeatability.

No need for welding wire and a protective atmosphere: There is no need for filling materials and shielding gas during welding, no pre-treatment of the surface of the casting parts before welding, no protective measures need to be applied during the welding process, which simplifies the welding process.

High dimension precision: Since friction stir welding is solid-phase welding, its heating process has the characteristics of high energy density and fast heat input.

Green welding method: The friction stir welding process does not produce arc radiation, smoke and spatter, and has low noise, which realizes the environmental protection of the welding process. Therefore, friction stir welding is called the "green welding method".

3. Application:

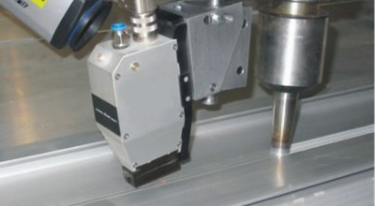

The picture shows the welding process of our current motor housing:

Friction stir welding technology can be applied to a variety of aluminum alloys, such as pure aluminum alloy 6061, 6063, casting aluminum alloy ADC12, A380, A356, etc.

In the automotive field: engine, chassis, gearbox housing, motor housing, cylinder head, etc.