A380 die-cast aluminum alloy is the most common special aluminum alloy because it combines easy casting mould, easy machining, good heat conduction, and other characteristics. Variable mobility, pressure bearing, and high temperature split resistance are very strong. It is widely used in various products, including chassis of motor equipment, engine brackets, gearboxes, furniture, generators and control arms, brackets, etc.

1. Material composition

JIS Standard | Cu | Si | Mg | Zn | Fe | Mn | Ni | Sn | Al |

A380 | 3.0-4.0 | 7.5-9.5 | 0.1 | 3.0 | 1.3 | 0.5 | 0.5 | 0.35 | Remain |

2. Mechanical properties

Alloy | Tensile strength Test | Hardness test | ||

Tensile strength MPa | Yield Strength MPa | Elongation % | Hardness HB | |

A380 | 324 | 160 | 3.5 | 80 |

3. Physical Properties

Material | Alloy | Density | Thermal Conductivity | Coefficient of Thermal Expansion | Electrical Conductivity | Process | |

Unit | g/cm3 | °C | W / m K | µm/m°K | % IACS | ||

Aluminum Die Casting Metals | 2.71 | 566 | 96 | 21.8 | 23.0 |

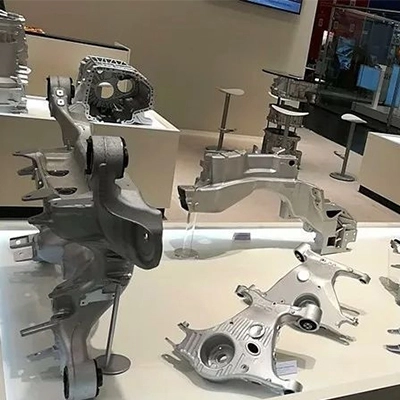

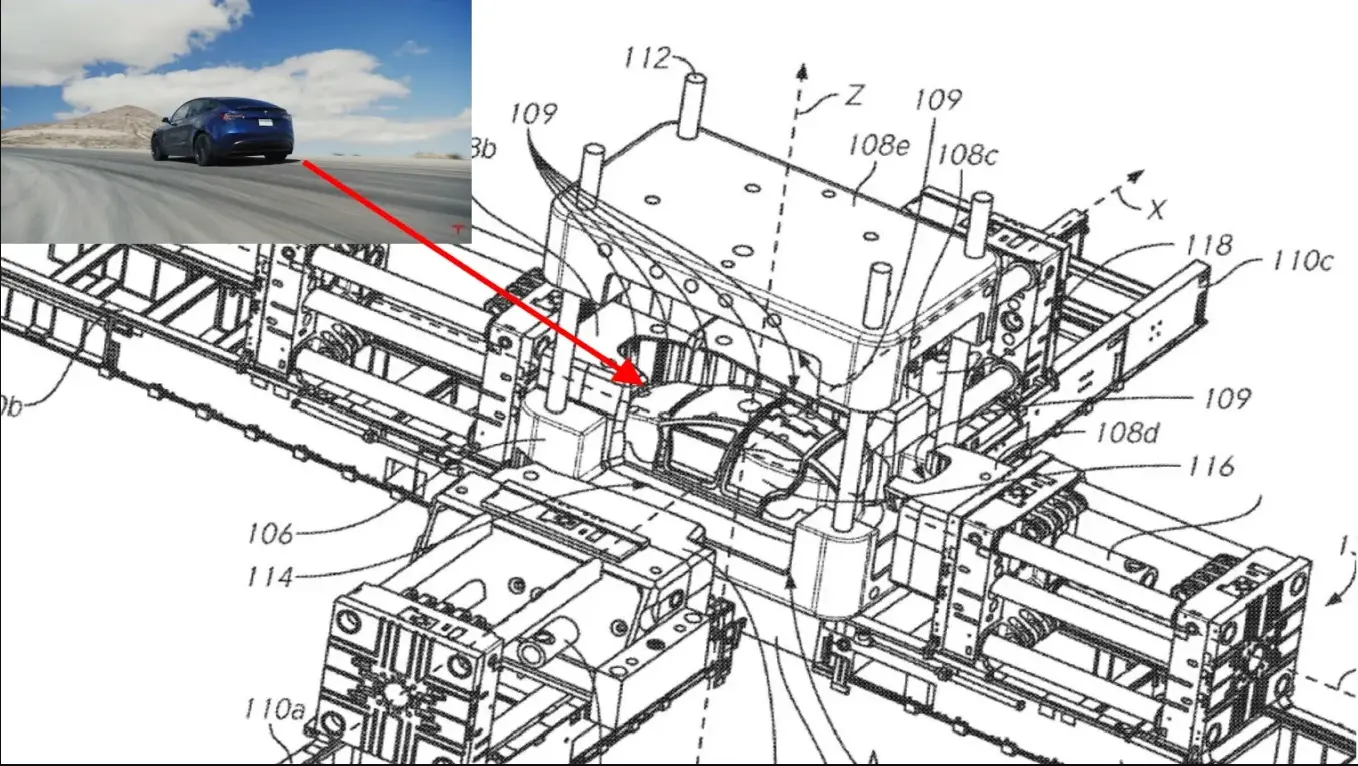

4. Application

A380 die-cast aluminum is widely used in various products, including chassis of motor equipment, engine brackets, gearboxes, furniture, generators and control arms and brackets etc.

5. Advantages

Excellent mechanical properties.

Good fluidity and filling

Good machinability

Generally good corrosion resistance.

Good dimensional accuracy and stable size

Good surface treatment characteristics.