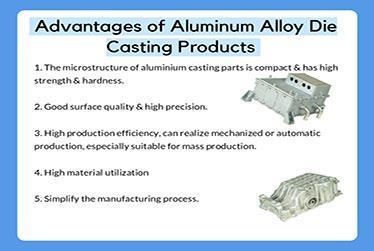

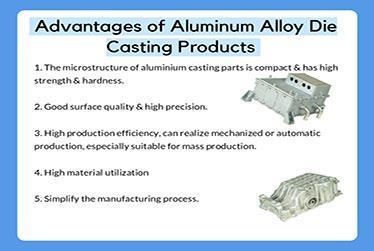

Because die casting is the filling of molten liquid metal in a very short time, it is cooled rapidly in die casting die and solidified and crystallized under high pressure. Therefore, the microstructure of aluminium casting parts near the surface layer is fine and dense, which makes aluminium casting parts have high strength, hardness, good wear resistance and corrosion resistance.

The dimensional accuracy of aluminium casting parts can reach the i13-i level, even ir9 level at the highest level; the surface roughness r-value of aluminium casting parts usually reaches o.8-3.2 μm or even O.4 μm. Aluminium casting parts have good interchangeability and can produce aluminium casting parts with complex shapes, clear outlines and thin walls and deep cavities. The minimum wall thickness of aluminium casting parts is 0.5mm. At the same time, it can cast clear characters and patterns.

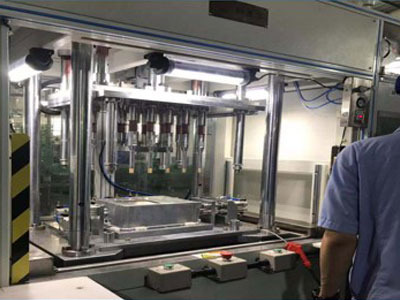

According to the size of the die casting machine, the cold chamber dies casting machine can die-cast 3100 times per hour, or even more. The hot chamber dies casting machine can die-cast 40-1000 times per hour.

Aluminium casting parts can be directly assembled and used without machining or with a small amount of machining, and the material utilization rate can reach 60% ~ 80%, or even higher, which means good economic benefits. Because of high precision, good surface quality, less machining allowance or assembly without machining, machining equipment and cost are reduced, and good economic benefits can be obtained.

Other inserts with special properties can be directly embedded in aluminium parts in automobile die casting production. It can not only meet the requirements of service performance, expand the use of products, but also reduce the assembly process and simplify the manufacturing process.