1. Status of Research on Aluminum Alloy Die Casting

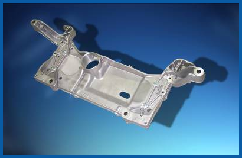

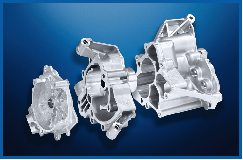

In recent years, the automobile, electronic and electrical appliances, aviation and other industries have developed very rapidly, making the demand for die-casting aluminum alloy has increased significantly, occupying more than 75% of the production of non ferrous alloy die casting. Take the automobile industry as an example, the body weight reduction can effectively save energy, in line with the concept of green travel in today's world, therefore, die-casting aluminum alloy widely replaced the traditional steel castings.

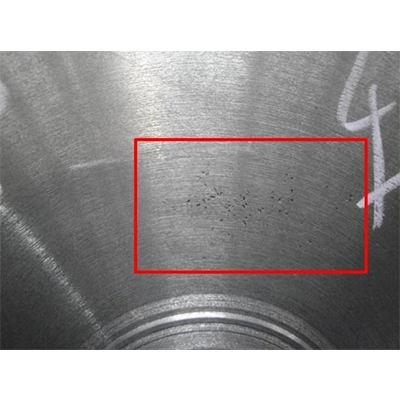

Die-cast aluminum alloys have low density, good electrical and thermal conductivity, malleability, corrosion resistance and oxidation resistance, but they also have disadvantages such as low plasticity and easy to stick to the film. Therefore, how to improve the performance of die-casting aluminum alloy is the key to the research of aluminum alloy. At this stage, there are two ways to improve the performance of die-casting aluminum alloy: improving the die-casting process and designing the composition.

2. How to Improve the Performance of Aluminum Alloy Die Casting

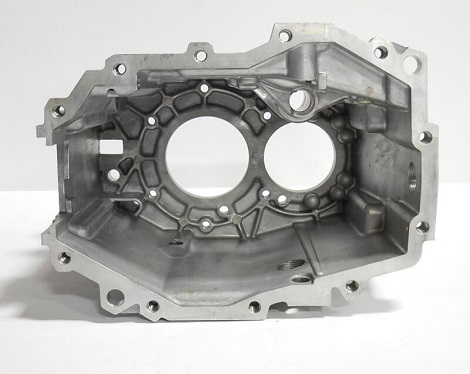

The die-casting process of aluminum alloy mainly includes high-pressure die casting, gravity die casting, liquid die forging, etc. Most of the die-casting process has been quite mature, so the improvement of die-casting process is not much to improve the performance of die-cast aluminum alloy. The composition design of aluminum alloy is another effective means to improve the performance of aluminum alloy. In these series of aluminum alloy die castings, adding Cu, Fe, Sr, Zr, Mn, Ti and other alloy elements can not only fragmentate the dendrites and refine the grains, but also eliminate the harmful effects of Fe and other elements, which can greatly improve the performance of aluminum alloy die castings.

3. Future Prospect of Aluminum Alloy Die Casting

With the continuous development of automobile, electronic and other industries and the continuous expansion of die-casting aluminum alloy application, the performance of aluminum alloy has put forward new requirements. By optimizing the combination of alloy elements, adding effective grain refining agent and perfecting the die-casting process are important means to improve the performance of aluminum alloys, and although some progress has been made, there are still many problems. After fully considering the practicality and economic feasibility, more high-performance and economical die-casting aluminum alloys can be developed to promote the development of die-casting aluminum alloys.