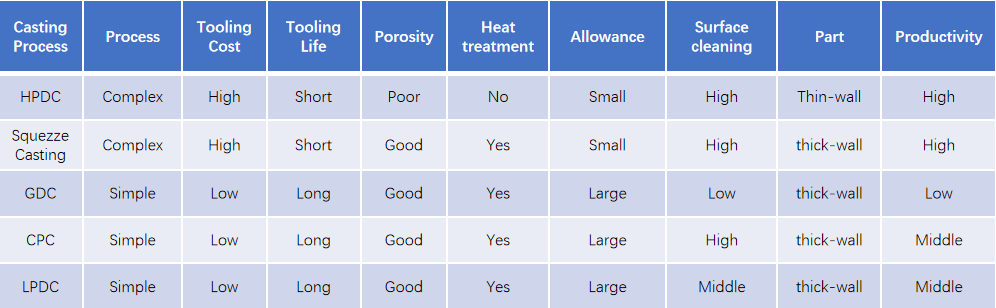

Classification of Die Casting Processes

1. Definition of High-pressure Die Casting

High-pressure casting is a casting method in which a 660-degree liquid aluminum alloy is poured into the press chamber of a die-casting machine to fill the cavity under high pressure and high speed, and then molded and crystallized under high pressure to obtain castings.

2. Definition of Liquid Die Forging

Liquid die forging, also called extrusion die casting, is a process in which semi-solid aluminum liquid at 300 degrees is filled at low speed from bottom to top under mechanical pressure, and solidifies and replenishes shrinkage sequentially under high pressure ( >100MPa ). Controlled filling and solidification are two important aspects of the liquid die forging process, low-speed filling and high-pressure solidification and shrinkage is the guarantee of the dense organization of liquid die forging castings.

3. Definition of Gravity Die Casting

Gravity die casting is a casting method that uses the earth's gravity to pour liquid metal into the cast metal, and crystallizes and solidifies under the action of gravity to form a casting.

4. Definition of Counter-pressure Casting

Counter-pressure casting is a casting method based on low-pressure casting, in which a sealed cover is placed over the mold and compressed air is introduced into the crucible and the cover at the same time, but the pressure inside the crucible is slightly higher, and the metal liquid inside the crucible is filled with the mold by the rising tube under the action of pressure difference and crystallized under the pressure.

5. Definition of Low-pressure Die Casting

Low-pressure casting is a casting method in which the liquid metal is filled and solidified under pressure to obtain a casting. Because the role of the pressure is low (generally 20 ~ 60kPa), so called low pressure casting.

Process Characteristics Comparison