The automotive industry is in a constant state of evolution, continually striving for greater efficiency, safety, and innovation. One of the driving forces behind this evolution is material science, specifically the use of advanced manufacturing processes. Among these processes, custom aluminum die casting stands out as a pivotal technology. At EMP, we're proud to be at the forefront of delivering high-quality, precision-engineered aluminum parts that are revolutionizing the automotive sector. In this blog, we’ll explore the various ways custom aluminum die casting is advancing automotive design and functionality.

As regulatory pressures for fuel efficiency and emissions reduction intensify, the automotive industry is increasingly turning to lightweight materials. Aluminum is one of the primary materials that fit this bill. Its excellent strength-to-weight ratio makes it ideal for creating durable yet lightweight vehicle components. Custom aluminum die casting allows manufacturers like EMP to produce intricate and high-strength parts that significantly reduce the overall weight of vehicles, thereby enhancing fuel efficiency and performance.

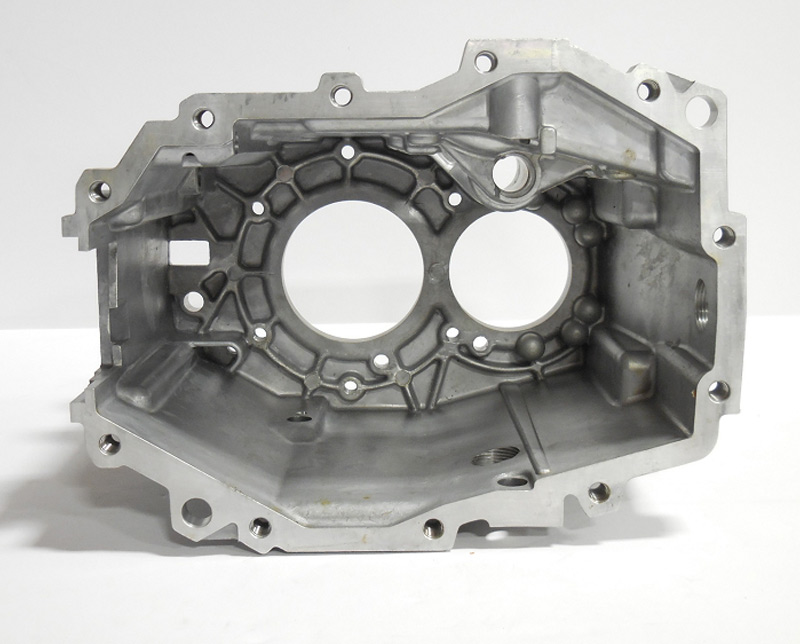

In automotive manufacturing, precision is not just a requirement but a necessity. The intricate and often complex geometries of automotive components demand a manufacturing process that offers both accuracy and repeatability. Custom aluminum die casting achieves this with remarkable efficiency. At EMP, our advanced die-casting technologies ensure that each part meets stringent quality standards. The result is a suite of components that contribute to the seamless operation and enhanced longevity of vehicles.

The ability to customize components to meet specific design parameters is another significant advantage of custom aluminum die casting. The automotive industry's push towards more innovative and efficient designs necessitates a flexible manufacturing process. Whether it's a unique engine component, a highly detailed trim piece, or a functional structure within the vehicle, EMP's custom aluminum die-casting process can produce a wide array of specialized parts. This versatility not only helps in achieving the desired aesthetic and functional attributes but also accelerates the design-to-production timeline.

Sustainability is becoming increasingly important for die casting in automotive industry, and aluminum is a highly recyclable material. Custom aluminum die casting supports sustainability goals by minimizing waste and enabling the reuse of scrap material. At EMP, our commitment to responsible manufacturing practices ensures that our processes are both environmentally friendly and cost-effective. Moreover, the durability of aluminum components means fewer replacements and repairs over the lifespan of the vehicle, contributing to long-term cost savings for manufacturers and consumers alike.

The ongoing advancements in automotive manufacturing are largely driven by technologies like custom aluminum die casting. From weight reduction and enhanced fuel efficiency to increased precision and improved sustainability, the benefits of this process are profound. At EMP, we're excited to be part of this journey, partnering with automotive manufacturers to deliver components that set new standards in quality and performance.

Whether you're in the automotive industry or another sector requiring high-quality, precision-engineered aluminum parts, custom aluminum die casting stands out as a superior manufacturing solution. Trust EMP to be your partner in innovation and excellence as we help drive the future of automotive advancements forward.