The automotive industry has always been synonymous with innovation and technological advancements. With the constant demand for light-weight materials that ensure durability, aluminum die-casting components have emerged as a game-changer. In this blog, we will explore the numerous benefits of aluminum die-casting components in the automotive industry and how they have revolutionized this sector.

One of the primary advantages of aluminum die-casting components is their light-weight nature. Compared to other materials like iron or steel, aluminum possesses an excellent strength-to-weight ratio, making it an ideal choice for automotive applications. The reduced weight of these components leads to enhanced fuel efficiency, lower emissions, and improved overall vehicle performance.

Aluminum exhibits exceptional thermal conductivity, making it an excellent material for heat dissipation. In the automotive industry, this property is of utmost importance due to the heat generated by engines, braking systems, and electrical components. By utilizing aluminum die-casting components, manufacturers can effectively manage heat dissipation, leading to improved performance and preventing overheating of crucial vehicle parts.

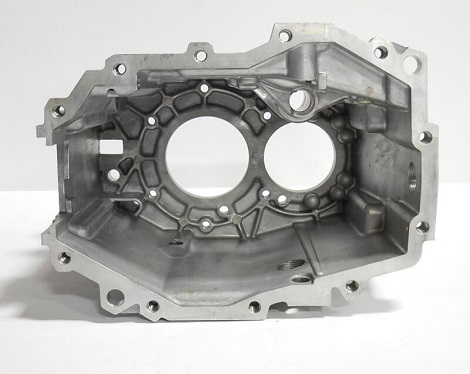

Aluminum die casting offers unparalleled design flexibility, enabling intricate and complex shapes to be produced with precision. This opens up a world of possibilities in terms of enhancing vehicle aesthetics and optimizing functionality. The ability to create sophisticated designs in complex automotive parts, such as engine components, transmission systems, and structural elements, ultimately translates into innovative and efficient vehicles.

In addition to its technical advantages, aluminum die-casting components also offer significant cost benefits to the automotive industry. They are comparatively cheaper to produce and require less post-processing, resulting in cost savings during manufacturing. Moreover, the longevity and durability of aluminum-based components contribute to reduced maintenance and replacement costs over the lifespan of a vehicle. These cost-efficiency advantages make aluminum die casting a preferred choice for automotive manufacturers.

Aluminum die-casting components have undoubtedly transformed the automotive industry, offering an array of benefits that other materials simply cannot match. From their light-weight nature and superior heat dissipation properties to their unparalleled design flexibility and cost-effectiveness, aluminum die casting components have solidified their place in the automotive sector. As technology continues to evolve, we can expect further advancements in the field of die-casting, revolutionizing the way automobiles are built and improving the overall driving experience for consumers around the world.

In a world where sustainable practices and fuel efficiency are paramount, aluminum die-casting components has emerged as a game-changer, propelling the automotive industry toward a greener and more sustainable future. So, it's no wonder that renowned brands like EMP are at the forefront of this transformative technology, contributing to the creation of next-generation vehicles that surpass expectations in terms of performance, efficiency, and longevity.